- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

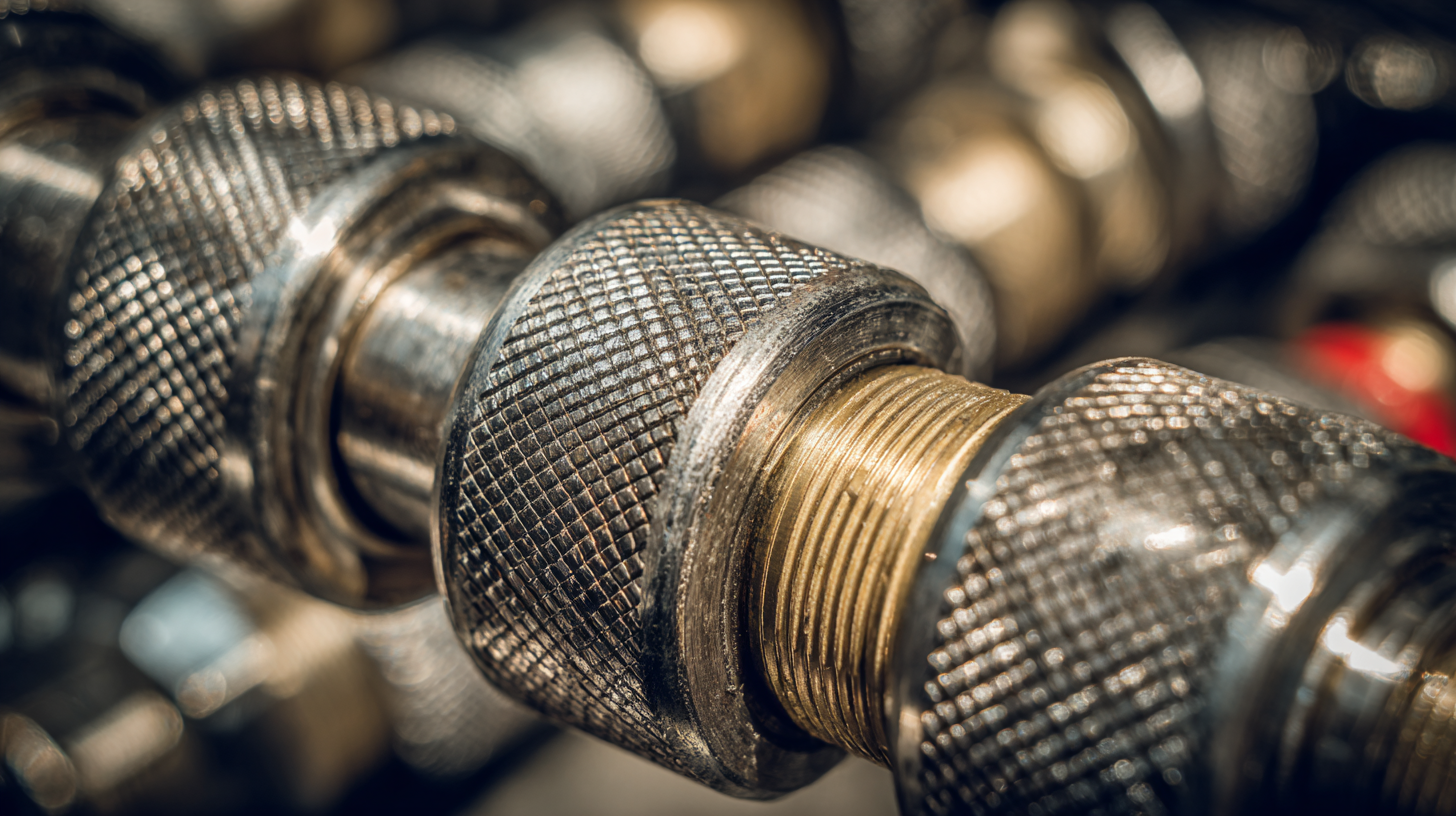

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

Navigating the 2025 Technology Trends in Industrial Hoses for Optimal Performance and Efficiency

In an era where efficiency and performance are paramount, the industrial hose sector stands on the cusp of transformative changes driven by technological advancements. According to a recent report by Grand View Research, the global industrial hose market is projected to reach USD 23.5 billion by 2025, growing at a CAGR of 5.4%. This growth is largely fueled by the expanding manufacturing sector and the increasing demand for durable and high-performance hoses that can withstand various applications. As industries emphasize sustainability and cost-effectiveness, innovations in material science and manufacturing processes are set to redefine the capabilities of industrial hoses. In this blog, we will explore the emerging technology trends in the industrial hose market, highlighting how companies can leverage these advancements to optimize performance and achieve unparalleled efficiency, all while ensuring adherence to high-quality standards exemplified by China’s reputed manufacturing output.

Impact of Emerging Materials on Industrial Hose Durability and Efficiency

As industries evolve, the demand for industrial hoses made from innovative materials becomes increasingly vital. Emerging materials, such as advanced polymers and composites, offer enhanced durability and resistance to harsh chemicals, extreme temperatures, and wear. These improvements lead to significant increases in the lifespan of hoses, reducing downtime resulting from replacements or repairs. The ability to withstand the rigors of various industrial applications not only optimizes performance but also ensures safer operations in demanding environments.

Moreover, the integration of smart materials into hose manufacturing has begun to revolutionize how businesses approach hose efficiency and monitoring. For instance, hoses embedded with sensors can provide real-time data on pressure, flow rate, and overall condition, enabling proactive maintenance and preventing catastrophic failures. This technological advancement underscores the importance of selecting the right materials that not only fulfill operational requirements but also contribute to the bottom line by enhancing productivity and reducing costs. As companies navigate the technological trends of 2025, focusing on the impact of these emerging materials will be crucial for achieving optimal performance in their industrial applications.

Navigating the 2025 Technology Trends in Industrial Hoses for Optimal Performance and Efficiency - Impact of Emerging Materials on Industrial Hose Durability and Efficiency

| Material Type | Durability (Years) | Temperature Resistance (°C) | Pressure Rating (psi) | Weight (lbs/ft) | Conductivity |

|---|---|---|---|---|---|

| EPDM Rubber | 10 | +120 | 300 | 0.5 | Insulative |

| Polyurethane | 8 | +80 | 250 | 0.4 | Insulative |

| PVC | 5 | +60 | 200 | 0.6 | Conductive |

| Silicone | 15 | +200 | 250 | 0.3 | Insulative |

Innovative Manufacturing Techniques Transforming the Hose Production Landscape

The landscape of industrial hose manufacturing is undergoing a significant transformation, driven by innovative techniques that enhance both performance and efficiency. Among these advancements, additive manufacturing, commonly known as 3D printing, is revolutionizing how hoses are produced. This technology allows for the creation of complex geometries that traditional methods cannot achieve, resulting in lighter, stronger hoses that can withstand extreme conditions. Furthermore, 3D printing reduces material waste and shortens production times, enabling manufacturers to respond more swiftly to market demands.

In addition to additive manufacturing, automation and robotics are redefining production lines in hose manufacturing. With precision engineering and automated assembly processes, manufacturers can ensure consistent quality and reduce human error. This shift not only improves operational efficiency but also allows companies to scale up production without compromising performance. As the industry embraces these innovative techniques, the focus remains on creating hoses that meet evolving standards for durability and reliability, addressing the diverse needs of sectors such as construction, agriculture, and automotive. The future of industrial hoses is indeed bright, fueled by technology that sets a new benchmark for quality and efficiency.

Smart Technology Integration: Enhancing Monitoring and Maintenance of Hoses

As the industrial sector continues to evolve, integrating smart technology into hose systems is becoming increasingly essential for monitoring and maintenance. By adopting advanced telemetry and sensor technologies, companies can gain real-time insights into the performance and condition of their hoses. This proactive approach enables early detection of potential issues, reducing the risk of leaks or failures that could lead to costly downtimes and safety hazards.

Moreover, the incorporation of data analytics allows for more efficient maintenance schedules based on actual usage patterns rather than arbitrary timelines. With predictive maintenance powered by AI algorithms, organizations can optimize their operations, ensuring that hoses are not only functioning at their best but are also replaced or serviced at the right time. This alignment of technology and operational needs not only enhances efficiency but also promotes sustainability by extending the life cycle of industrial hoses.

Sustainability in Industrial Hoses: Eco-Friendly Innovations for 2025

As the industrial sector evolves, sustainability is becoming increasingly central to the development of industrial hoses. According to a recent market analysis by Grand View Research, the global industrial hose market is expected to reach $19.82 billion by 2025, with eco-friendly product lines growing significantly in demand. Innovations such as bio-based materials and recyclable designs are being prioritized as manufacturers strive to reduce their environmental footprint while maintaining high performance standards.

In 2025, we anticipate a surge in the adoption of sustainable materials such as thermoplastic elastomers that not only boast enhanced durability but also offer recyclability. Research from the American Society for Testing and Materials indicates that hoses developed from these materials can lead to a significant decrease in greenhouse gas emissions, potentially reducing a company's carbon footprint by as much as 30%. Additionally, the integration of smart technologies in hose manufacturing, such as sensors that monitor wear and tear, empowers companies to prolong the lifecycle of hoses and minimize waste, presenting a formidable advantage in resource efficiency.

This emphasis on sustainability is not just a trend but a necessity driven by regulatory changes and consumer preferences favoring environmentally friendly products. As such, businesses in the industrial segment must navigate these advancements to enhance efficiency while championing ecological responsibility in their operations by 2025.

Meeting Global Standards: Navigating Compliance in the Global Hose Market

The global hose market is increasingly driven by stringent compliance standards and regulations aimed at ensuring safety and quality. According to a report by MarketsandMarkets, the industrial hoses market is projected to reach USD 18.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.8%. This growth highlights the critical importance of adhering to international compliance protocols like ISO 9001 and FDA regulations. These standards not only enhance product quality but also provide a competitive edge in markets where safety and reliability are paramount.

Moreover, the integration of advanced materials and manufacturing processes has raised the bar for compliance. For instance, the rise of environmentally friendly and sustainable hose materials has become a compliance prerequisite for many industries. A study by Grand View Research indicates that the eco-friendly hose segment is expected to grow by 5.2% from 2020 to 2027, driven by regulations aimed at reducing environmental impact. This trend necessitates that businesses not only invest in compliant products but also remain agile in adapting to evolving regulatory landscapes to optimize overall performance and efficiency in their operations.

Navigating the 2025 Technology Trends in Industrial Hoses

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry