- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

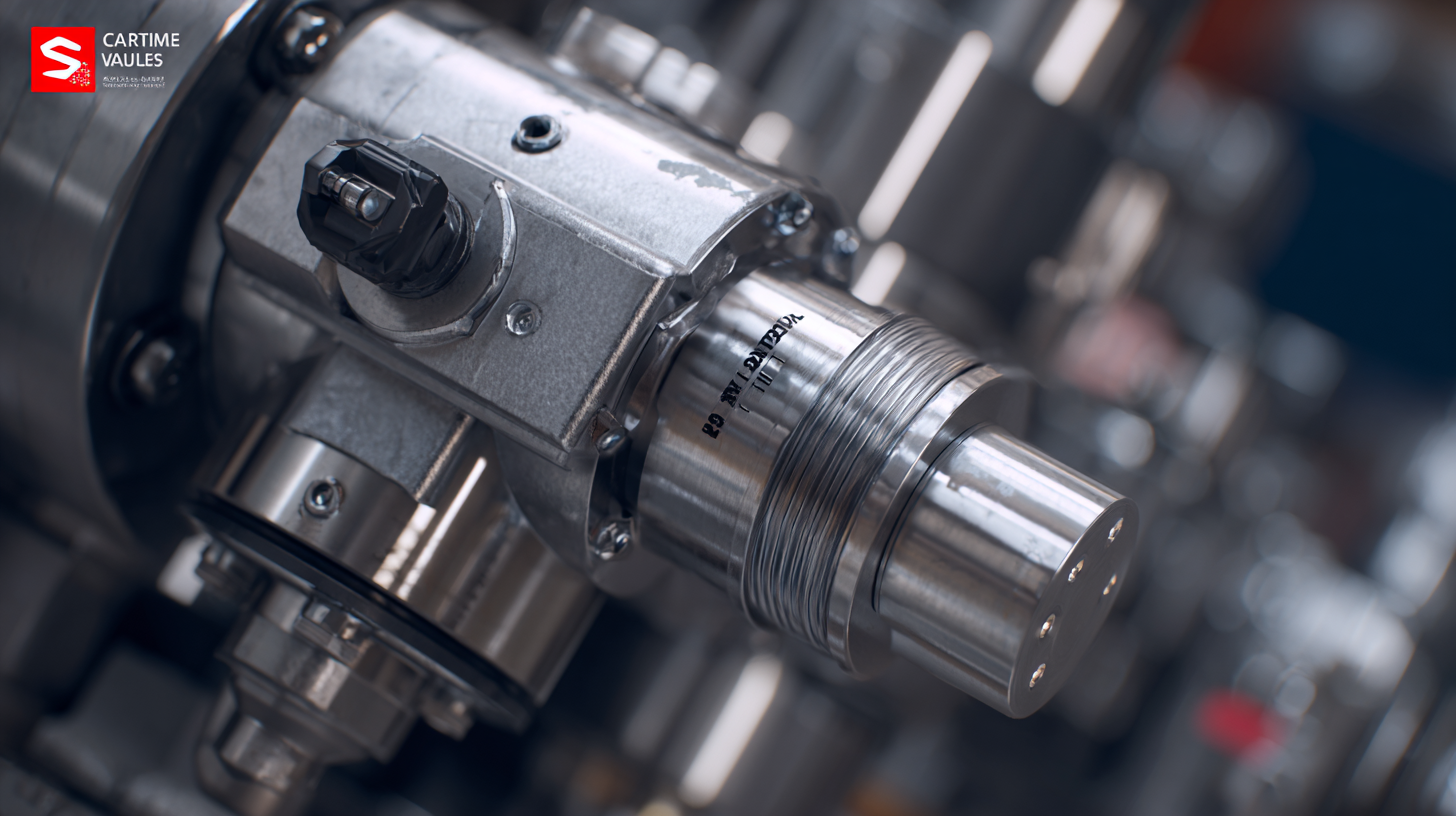

5 Ways Best Cartridge Valves Improve Your Industrial Efficiency

In the ever-evolving landscape of industrial operations, maximizing efficiency is paramount. With industries striving to enhance their productivity metrics, the role of advanced hydraulic components cannot be overlooked. Cartridge valves, known for their compact design and superior performance, are emerging as a critical solution for improving operational efficiency.

According to a report by MarketsandMarkets, the global hydraulic valves market is projected to reach USD 4.74 billion by 2025, driven largely by innovations in cartridge valve technology. These valves not only offer enhanced space optimization but also contribute to reduced energy consumption and improved system responsiveness.

In this blog, we will explore five ways in which cartridge valves can significantly enhance your industrial efficiency, driving both performance and profitability in an increasingly competitive market.

Understanding Cartridge Valves and Their Role in Industrial Efficiency

Cartridge valves play a pivotal role in enhancing industrial efficiency, particularly in hydraulic systems where precise control and reliable performance are paramount. According to a recent market research study, the global industrial hydraulic equipment market is projected to reach USD 52.6 billion by 2033, growing at a CAGR of 5.7%. This growth underscores the rising demand for optimized hydraulic solutions, such as cartridge valves, which streamline operations by integrating multiple functions into a single compact unit. These valves reduce the number of components necessary for system functionality, thus minimizing potential points of failure and maintenance requirements.

The significance of cartridge valves is further highlighted in the context of the broader hydraulic market trends. The servo valve market, for instance, is anticipated to surpass sales revenue of USD 3,177.48 million by 2031, fueled by the increasing need for precise fluid control across diverse industrial applications. As industries seek to enhance performance and sustainability, cartridge valves emerge as a critical component, allowing for better energy efficiency and reduced operating costs. By adopting advanced technologies like digital hydraulic transformers, manufacturers can optimize fluid power systems and drive further growth in this evolving sector.

Key Features of High-Performance Cartridge Valves for Optimal Operations

High-performance cartridge valves are essential components for optimizing industrial operations, offering several key features that enhance efficiency and productivity. One significant advantage of these valves is their compact design, allowing for reduced installation space while maintaining high flow rates. According to a recent industry report by the International Fluid Power Society, implementing cartridge valves can improve overall system efficiency by up to 20%, resulting in minimized energy consumption and operational costs.

High-performance cartridge valves are essential components for optimizing industrial operations, offering several key features that enhance efficiency and productivity. One significant advantage of these valves is their compact design, allowing for reduced installation space while maintaining high flow rates. According to a recent industry report by the International Fluid Power Society, implementing cartridge valves can improve overall system efficiency by up to 20%, resulting in minimized energy consumption and operational costs.

Another critical feature of cartridge valves is their versatility. They are available in various configurations, allowing engineers to customize systems according to specific application needs. This adaptability leads to streamlined processes and less downtime during machine maintenance. Furthermore, the use of advanced materials and surface treatments in manufacturing these valves enhances their durability, ensuring long-lasting performance in demanding environments. Regular maintenance can further boost valve lifespan and operational efficiency.

Tip: To maximize the benefits of cartridge valves, consider implementing predictive maintenance practices using IoT technology to monitor valve performance continuously.

Additionally, integrating cartridge valves with advanced control systems can facilitate real-time adjustments, optimizing flow rates and pressure settings based on operational demands. This integration supports the development of smarter systems, ultimately leading to a more efficient industrial environment.

Tip: Always consult with engineers to ensure proper selection and installation of cartridge valves, as this will play a pivotal role in achieving desired efficiency gains.

How Cartridge Valves Reduce Downtime and Enhance Maintenance Practices

Cartridge valves are essential components in hydraulic systems, renowned for their ability to enhance maintenance practices and reduce downtime. By consolidating multiple functions into a single unit, these valves simplify the design and installation processes. This modular approach allows for quicker replacements and repairs, minimizing the time machinery is out of service. Additionally, the integration of advanced diagnostic features in many cartridge valves can provide real-time insights into system performance, enabling proactive maintenance that anticipates issues before they escalate into costly failures.

Moreover, the ease of access and installation makes cartridge valves an attractive option for industrial operators. When a valve needs to be replaced, technicians can often do so quickly and without extensive disassembly of surrounding components. This not only speeds up the service process but also reduces the need for specialized tools, streamlining maintenance operations. As industries strive to maximize operational efficiency, the adoption of cartridge valves stands out as a practical solution to enhance productivity while keeping maintenance costs low.

5 Ways Best Cartridge Valves Improve Your Industrial Efficiency

| Aspect | Benefit | Impact on Efficiency | Maintenance Frequency |

|---|---|---|---|

| Reduced Leakage | Minimized fluid loss | Improved system performance | Quarterly |

| Enhanced Response Time | Faster actuation | Higher operational speed | Monthly |

| Simplified Maintenance | Easier component replacement | Reduced downtime | As needed |

| Reduced Energy Consumption | Lower operating costs | Increased sustainability | Annual |

| Improved Component Lifespan | Longer service intervals | Cost-effective | Bi-annual |

The Impact of Accurate Flow Control with Cartridge Valves on Production

Efficient flow control is critical in industrial settings, where even minor fluctuations can lead to significant production losses. According to a report by the International Society for Automation, industries that implement precise flow control systems can improve operational efficiency by up to 20%. Cartridge valves, known for their modular design and reliability, provide exceptional accuracy in regulating fluid flow pressure and direction. This high level of precision translates directly into enhanced production rates and consistent product quality.

Moreover, the economic impact of accurate flow control cannot be underestimated. A study by the National Fluid Power Association revealed that companies utilizing advanced cartridge valve technology experienced a reduction in energy consumption by about 15%, leading to substantial cost savings over time. These valves minimize wastage and improve the lifespan of hydraulic systems by ensuring that equipment operates under optimal conditions. By adopting cartridge valves, industries not only optimize their processes but also contribute to sustainability by conserving resources and reducing operational costs.

5 Ways Best Cartridge Valves Improve Your Industrial Efficiency

Integrating Cartridge Valves into Existing Systems for Improved Workflow

Integrating cartridge valves into existing hydraulic systems offers a straightforward way to enhance industrial efficiency. These valves are designed for easy installation in a wide range of configurations, allowing for rapid upgrades without the need for complete system overhauls. By slotting cartridge valves directly into positions within current manifolds or circuits, companies can avoid costly downtime while simultaneously benefiting from improved performance and reliability.

Moreover, cartridge valves streamline workflow by minimizing leakage and reducing energy consumption. Their compact design not only saves space but also optimizes fluid flow, which can enhance response times in hydraulic applications. By adopting these advanced valves, facilities can significantly reduce maintenance efforts and costs, as cartridge valves typically require less frequent servicing compared to traditional valve systems. This integration is not merely an upgrade; it's a strategic move that fosters greater operational efficiency and drives productivity in industrial environments.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry