- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

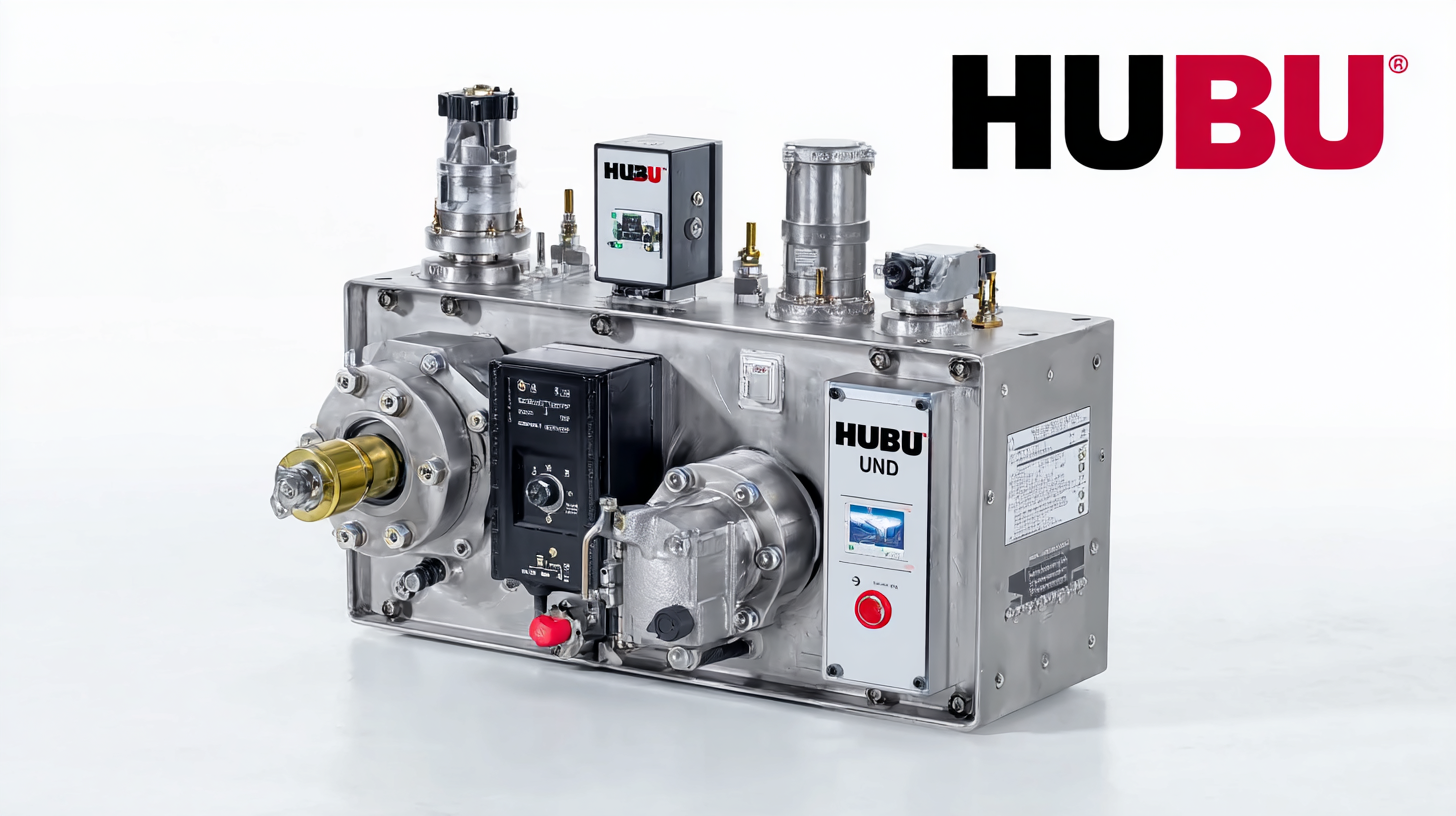

Understanding the Best Hydraulic Unit for Optimal Performance in Industrial Applications

In the rapidly evolving landscape of industrial applications, the importance of selecting the right Hydraulic Unit cannot be overstated. According to a recent report by Markets and Markets, the global hydraulic equipment market is projected to reach USD 55.4 billion by 2025, driven by the increasing demand for efficient hydraulic systems across various sectors such as construction, manufacturing, and automotive. As industries strive for optimal performance and reliability, understanding the technical specifications and operational capabilities of hydraulic units becomes essential.

This ultimate guide delves into the key features, benefits, and considerations for maximizing the efficiency of hydraulic units, ultimately supporting the technological trends anticipated in 2025 and beyond. Emphasizing the critical role of hydraulic units in enhancing productivity and sustainability, this article aims to equip professionals with the knowledge necessary to make informed decisions that align with the future of industrial operations.

Key Factors in Selecting a Hydraulic Unit for Industrial Applications

When selecting a hydraulic unit for industrial applications, it is crucial to consider several key factors that can significantly impact performance and efficiency. One primary consideration is the type of hydraulic fluid system being used, as current advancements in smart fluid hydraulics demonstrate that integrating smart pumps can optimize energy efficiency and reduce emissions. The global automotive hydraulic system market, for instance, was valued at approximately USD 43.71 billion in 2023 and is projected to grow at a CAGR of 3.9% through 2030, highlighting the continuous demand for efficient hydraulic solutions.

Additionally, the evolution of hydraulic technologies poses challenges and opportunities for industries reliant on hydraulic systems. For example, the transition from hydraulic to electric actuators has gained traction due to their precision and reliability. Industries are increasingly exploring remote actuation systems and their benefits in applications like wearable assistive devices. Staying informed about these advancements, as well as understanding the specific requirements for various applications, is essential for selecting the right hydraulic unit. These considerations ensure optimal performance and sustained operational efficiency in a competitive industrial landscape.

Importance of Hydraulic Unit Specifications for Enhanced Performance

When considering hydraulic units for industrial applications, the importance of specifications cannot be overstated. According to a report by the International Fluid Power Society, the efficiency of hydraulic systems can swing drastically based on the selection of hydraulic unit specifications, with performance fluctuations ranging from 15% to 30%. Optimal performance hinges on understanding parameters such as flow rate, pressure output, and temperature limits, which directly influence system responsiveness and energy consumption.

Research published by the National Fluid Power Association emphasizes that improper specification can lead to increased operational costs and equipment downtime. For instance, a mismatch in flow rate and required system pressure can result in significant energy wastes, with estimates suggesting potential savings of up to 20% on operational costs when units are correctly specified. Additionally, maintaining a hydraulic unit that adheres to industry standards not only enhances performance but also extends the lifespan of the equipment, thereby reducing the total cost of ownership.

Case Studies: Successful Implementations of Hydraulic Units in Industry

In modern industrial applications, hydraulic units have become pivotal for ensuring operational efficiency and sustainability. Case studies across various industries offer compelling examples of how these units have been successfully implemented to optimize performance. For instance, in the construction sector, companies have adopted advanced hydraulic systems that enhance productivity while minimizing environmental impacts. These systems not only improve force delivery but also incorporate energy-saving technologies, leading to lower operational costs and reduced water usage—an essential factor in today's focus on resource conservation.

Moreover, the rapid growth of the hydraulics market indicates a shift in industry practices towards more sophisticated, data-driven approaches. The integration of predictive maintenance technologies has allowed companies to anticipate issues before they escalate, significantly enhancing asset reliability. Industrial sectors, including pharmaceuticals and food manufacturing, have reported measurable improvements when leveraging hydraulic units in conjunction with digital maintenance solutions. By examining these case studies, it’s clear that the effective deployment of hydraulic units can drive substantial benefits, positioning businesses not only for increased productivity but also for greater sustainability in their operations.

Comparative Analysis of Hydraulic Units Across Different Industrial Sectors

The hydraulic unit market is experiencing significant growth, driven by diverse industrial applications ranging from construction to manufacturing. According to recent reports, China's hydraulic market accounted for 30.2% of the global market share, highlighting its rapid development in recent years, with a total output value reaching approximately 641 billion yuan by 2019. This impressive figure reflects not only domestic consumption but also a growing export potential as industries evolve and demand for hydraulic solutions increases.

In addition to the burgeoning domestic market, forecasts indicate a dynamic outlook for hydraulic oil, projected to grow from $10.44 billion in 2024 to over $22.82 billion by 2037, with a compound annual growth rate exceeding 6.2% during the forecast period. This growth is largely attributed to the ongoing expansion of industrial sectors that increasingly rely on hydraulic systems for efficiency and performance. Furthermore, advancements in hydraulic components, including the development of high-pressure cylinders and hydraulic pumps, signify a shift toward more sophisticated and reliable hydraulic units tailored to meet the specific needs of various industries. As businesses seek optimal performance, comparative analyses of hydraulic units across sectors will become crucial in identifying the best technologies to invest in.

Maintenance Best Practices for Prolonging Hydraulic Unit Lifespan and Efficiency

Effective maintenance practices are crucial for prolonging the lifespan and efficiency of hydraulic units in industrial applications. According to a report from the International Fluid Power Society, improper maintenance can lead to a 20-30% decrease in hydraulic system performance over time. Regular inspections and timely replacement of hydraulic fluids can mitigate wear and tear, ensuring that the unit operates within its optimal parameters. The right fluid not only lubricates the system but also plays a vital role in heat dissipation and contamination control.

Incorporating systematic maintenance schedules is essential for minimizing downtime. The Hydraulic Institute recommends conducting routine checks every three months, which can significantly enhance operational reliability. These checks should include monitoring fluid levels, inspecting for leaks, and testing system pressure to identify potential issues before they escalate. Additionally, implementing proper storage protocols for hydraulic components can further extend their service life, with data suggesting that components stored under ideal conditions can last up to 50% longer. Prioritizing these best practices can lead to increased efficiency and reduced operational costs in industrial applications.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry