- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

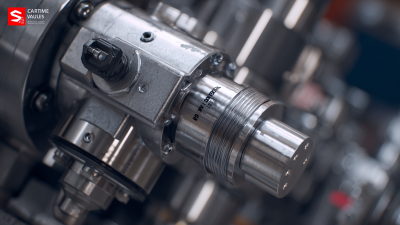

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

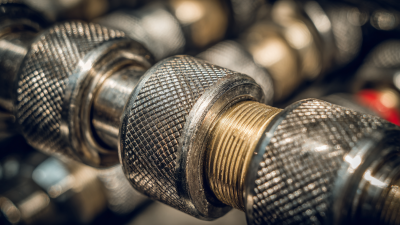

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

How to Choose the Right Hydraulic Hoses for Your Industrial Applications

Selecting the correct hydraulic hoses for industrial applications is crucial for ensuring efficient operation and safety in hydraulic systems. According to a report by MarketsandMarkets, the global hydraulic hose market is projected to grow from USD 10.61 billion in 2020 to USD 13.05 billion by 2025, reflecting an increasing demand across various sectors such as manufacturing, construction, and agriculture. Hydraulic hoses are integral components that transmit hydraulic fluid and are designed to withstand high pressure and fluctuating temperatures. Understanding the different types of hydraulic hoses available, as well as their specific applications and limitations, can significantly impact the performance and longevity of industrial equipment. This blog will guide you through the essential considerations for choosing the right hydraulic hoses, ensuring that your systems operate safely and efficiently.

Selecting the correct hydraulic hoses for industrial applications is crucial for ensuring efficient operation and safety in hydraulic systems. According to a report by MarketsandMarkets, the global hydraulic hose market is projected to grow from USD 10.61 billion in 2020 to USD 13.05 billion by 2025, reflecting an increasing demand across various sectors such as manufacturing, construction, and agriculture. Hydraulic hoses are integral components that transmit hydraulic fluid and are designed to withstand high pressure and fluctuating temperatures. Understanding the different types of hydraulic hoses available, as well as their specific applications and limitations, can significantly impact the performance and longevity of industrial equipment. This blog will guide you through the essential considerations for choosing the right hydraulic hoses, ensuring that your systems operate safely and efficiently.

Understanding the Different Types of Hydraulic Hoses Available

When selecting hydraulic hoses for industrial applications, it’s crucial to understand the various types available. The most common types include rubber hoses, thermoplastic hoses, and stainless steel hoses. Rubber hoses are known for their flexibility and resistance to abrasion, making them ideal for general hydraulic applications. Thermoplastic hoses, on the other hand, are lightweight and resistant to chemical exposure, suitable for environments with stringent cleanliness requirements. Lastly, stainless steel hoses offer exceptional durability and can withstand extreme temperatures and pressures, making them perfect for heavy-duty applications.

Tips for choosing the right hydraulic hose include assessing the operating environment and pressure requirements. Ensure that the hose material aligns with the chemicals and temperatures it will encounter. Additionally, consider the hose's bend radius; a hose that's too rigid for its application could lead to premature wear or failure. Another important aspect is the coupling method; selecting the appropriate fittings will guarantee a secure connection and reduce the risk of leaks.

Always consult manufacturer specifications to ensure compatibility and safety. Investing in high-quality hoses and regularly inspecting them can prevent costly downtimes and maintain the efficiency of your industrial systems. Remember, proper selection and maintenance are key to achieving optimal performance in hydraulic applications.

Key Factors to Consider When Selecting Hydraulic Hoses for Your Needs

When selecting hydraulic hoses for industrial applications, understanding key factors is essential to ensure safety and efficiency. One critical consideration is the hose material. According to a report by the Fluid Power Institute, rubber hoses provide superior resilience under heat and pressure, making them ideal for high-temperature applications where flexibility is crucial. On the other hand, thermoplastic hoses are lighter and more resistant to abrasion, offering advantages in environments with high wear and tear.

Another significant factor is pressure rating. It is imperative to choose a hose that can withstand the maximum pressure of your system, with a safety margin. The National Fluid Power Association recommends selecting hoses with a pressure rating of at least 1.5 times the maximum operating pressure. Additionally, compatibility with fluids is vital; hoses must be able to resist the chemical composition of the fluids they will transport. The latest industry analysis shows that improper hose selection can lead to 20% of hydraulic failures, underlining the need for careful consideration to avoid costly downtimes and ensure optimal performance.

Exploring the Material Specifications of Hydraulic Hoses

When selecting hydraulic hoses for industrial applications, understanding material specifications is crucial to ensure performance and safety. Hydraulic hoses are typically constructed from a combination of synthetic rubber, thermoplastic, or metal, each offering distinct advantages based on the operating environment. According to a report by the International Organization for Standardization (ISO), hoses made from synthetic rubber exhibit superior resistance to heat and abrasion, making them ideal for high-pressure hydraulic systems operating in extreme conditions.

Additionally, the selection of hose reinforcements—such as polyester or steel wire—can significantly influence their durability and flexibility. The American National Standards Institute (ANSI) suggests that hoses reinforced with steel wire are best suited for high-pressure and high-temperature applications since they can withstand significant stress without compromising integrity. Conversely, for lower pressure scenarios, thermoplastic hoses provide a lightweight and flexible option, suitable for applications where maneuverability is essential. Understanding these material specifications not only maximizes the longevity and reliability of hydraulic systems but also enhances operational efficiency across various industrial sectors.

How to Choose the Right Hydraulic Hoses for Your Industrial Applications - Exploring the Material Specifications of Hydraulic Hoses

| Material Type | Temperature Range (°C) | Pressure Rating (psi) | Flexibility | Common Applications |

|---|---|---|---|---|

| Rubber | -40 to 100 | 3000 | Good | Construction, Agriculture |

| Thermoplastic | -50 to 90 | 4000 | Excellent | Mining, Light Industrial |

| PVC | -10 to 60 | 1500 | Moderate | Water Transfer, Chemical Handling |

| Steel Braided | -40 to 100 | 5000 | Moderate | Heavy Machinery, Oil & Gas |

| Aramid Reinforced | -40 to 100 | 7000 | Good | High Pressure Applications |

Evaluating Pressure and Temperature Ratings for Optimal Performance

When selecting hydraulic hoses for industrial applications, understanding the pressure and temperature ratings is crucial for ensuring optimal performance. According to the Rubber Manufacturers Association (RMA), hose failure can result in significant downtime and safety hazards, making it essential to evaluate these ratings carefully. Hydraulic hoses are often rated for specific maximum pressure and temperature limits, typically detailed in industry standards such as SAE J517. For instance, a standard hydraulic hose might have a pressure rating ranging from 3,000 to 6,000 psi, depending on its construction and intended use.

**Tip:** Always choose a hydraulic hose that exceeds the maximum pressure requirements of your system by at least 25%. This extra capacity provides a safety margin and can help prevent potential failures.

In addition to pressure ratings, temperature compatibility is another vital aspect. Hydraulic systems can operate in extreme conditions, sometimes reaching temperatures up to 200°F and beyond. The American Society for Testing and Materials (ASTM) provides guidelines on the temperature ratings for different materials used in hose construction. Selecting a hose that can withstand the specific temperature range of your application helps maintain system efficiency and longevity.

**Tip:** Regularly monitor the temperature and pressure of your hydraulic system. Utilizing gauges and data loggers can provide insights that help you make informed decisions about hose maintenance or replacements.

Common Mistakes to Avoid When Choosing Hydraulic Hoses for Industrial Use

When selecting hydraulic hoses for industrial applications, it's crucial to avoid common mistakes that can lead to performance issues and costly downtime. One of the most frequent errors is neglecting to consider the working pressure and temperature ratings. Each hydraulic system has specific requirements, and using a hose that cannot withstand the necessary pressure or temperature can lead to catastrophic failures. Always check the specifications and ensure that the hose is designed for your operational conditions.

Another common mistake is overlooking the compatibility of the hose materials with the fluids being transported. Different hydraulic fluids can react adversely with certain hose materials, leading to degradation and leaks. It's essential to match the hose material with the fluid type to ensure longevity and reliability.

Lastly, failing to account for the hose's bend radius can also cause problems. A tight bend can restrict fluid flow and put undue stress on the hose, ultimately leading to premature failure. Therefore, taking the time to evaluate these factors will help you select the right hydraulic hoses for your industrial needs.

Related Posts

-

Exploring the Best High Pressure Hydraulic Hose Alternatives for Diverse Industrial Applications

-

Top 10 Directional Control Valve Manufacturers from China Featured at the 137th Canton Fair

-

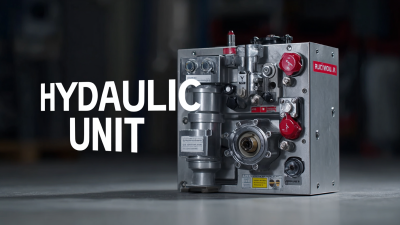

Understanding the Best Hydraulic Unit for Optimal Performance in Industrial Applications

-

Navigating the 2025 Technology Trends in Industrial Hoses for Optimal Performance and Efficiency

-

Hydraulic Fittings Showcase Success at the 137th Canton Fair Set to Drive International Trade Growth

-

5 Ways Best Cartridge Valves Improve Your Industrial Efficiency

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry