- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

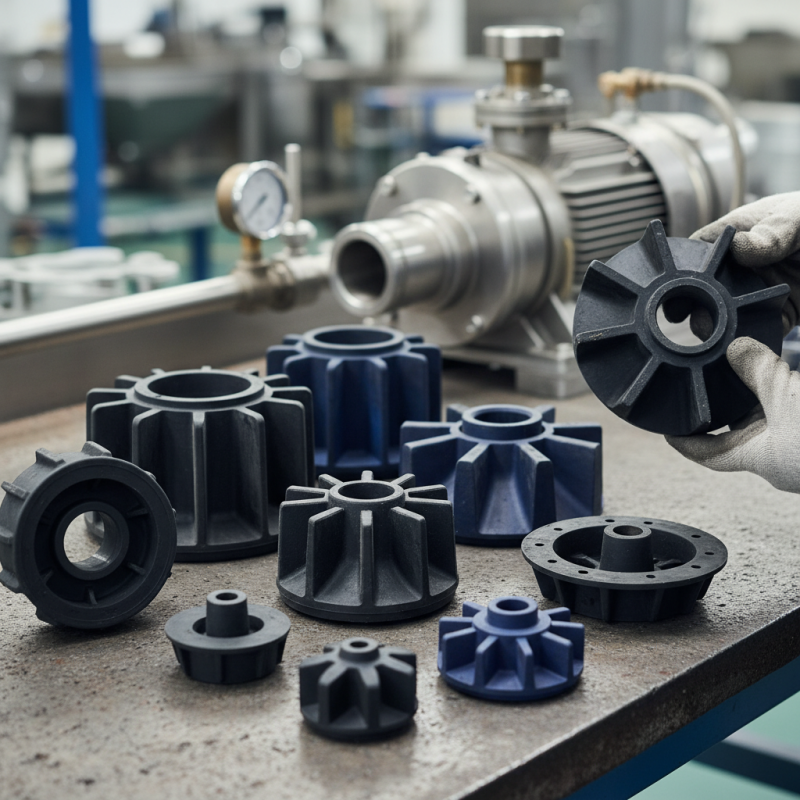

How to Choose the Right Rubber Pump Impeller for Your Needs?

Choosing the right Rubber Pump Impeller is crucial for optimal performance. With various options available, it can be challenging to make a decision. Factors such as material, size, and design all play significant roles. Rubber impellers are particularly popular due to their resistance to corrosion and wear.

Consider where the pump will be used. Each application has unique demands. For example, water transfer may differ from chemical processing. Understanding these situations helps narrow down choices. It’s easy to overlook details. Yet, the right impeller can enhance efficiency and prolong pump life.

Many people make mistakes when selecting their impeller. They may focus solely on price or availability. However, these elements should not compromise on quality. A thorough assessment of needs is vital. In the end, a suitable Rubber Pump Impeller makes all the difference in achieving desired results.

Understanding the Types of Rubber Pump Impellers Available

When selecting a rubber pump impeller, it's essential to understand the types available. There are mainly two categories: open and closed impellers. Open impellers have vanes that are exposed, offering high efficiency. They excel in handling solids and slurries, making them ideal for wastewater applications. Industry reports indicate that open impellers can increase efficiency by up to 15%.

Closed impellers have their vanes enclosed between two disks. This design results in higher pressure and flow rates. Many industries prefer closed impellers for clean water applications. They tend to minimize wear and can last longer than open types. However, they might struggle with large particulates. A study showed that closed impellers can be 10% less efficient in handling solids compared to open ones.

Another factor is the material composition. Rubber blends vary widely. Some offer higher resilience to chemicals, while others focus on temperature resistance. The choice impacts lifecycle costs significantly. Reports indicate that using the right rubber blend can extend the impeller life by 20%. It's clear that understanding these types can impact performance and maintenance efforts.

Evaluating Impeller Size, Shape, and Design for Your Application

Choosing the right rubber pump impeller involves careful evaluation of size, shape, and design. Each application presents unique challenges that the impeller must address. Size is critical; it determines the flow rate and pressure. A small impeller may not provide enough flow, while a large one can cause excessive wear on the pump.

The shape of the impeller influences efficiency. Closed impellers generally offer better performance due to their design. However, they might also be more prone to clogging. Open impellers can handle solids but may waste energy. Designers often face a trade-off between efficiency and versatility.

Material selection is another important factor. Rubber impellers provide excellent resilience and can handle harsh environments. However, they may wear out faster compared to metal counterparts in abrasive conditions. Not every impeller will suit every application perfectly. Evaluation and testing are key in finding the right balance for your specific needs.

Impeller Size and Design Comparison for Rubber Pumps

Assessing Material Compatibility and Performance Requirements

When choosing a rubber pump impeller, material compatibility is crucial. Different fluids can react with various rubber types. For instance, oils may degrade some rubbers but be fine with others. It’s essential to know what the impeller will face. Test the rubber against the fluid to ensure it won’t break down over time.

Performance requirements also play a vital role. Consider the flow rate and pressure needed for your system. A higher flow might require a specific impeller design. Think about how wear and tear will affect efficiency. An impeller might work well initially but may falter under pressure.

You may need to evaluate multiple options before settling on one. Gathering feedback from experienced users can help. But remember—what works for one situation might not suit another. Always allow room for adjustments and reconsideration based on real-world performance.

Considering Flow Rate and Efficiency Factors in Impeller Selection

Choosing the right rubber pump impeller involves careful consideration of flow rate and efficiency. The flow rate is crucial. It determines how much fluid the impeller will move. If the flow rate is too low, the system underperforms. If it's too high, it may lead to damage. Aim for a balance that suits your application.

Efficiency factors play a significant role. The design of the impeller can affect how efficiently it converts energy into fluid movement. A well-designed impeller minimizes energy losses. However, achieving high efficiency isn't always easy. Sometimes, there are trade-offs between flow rate and efficiency.

Tips: Always test your impeller in real conditions. Watch for any unusual vibrations or noises. These can indicate inefficiencies. Also, consider materials carefully. Not every rubber type performs well in every environment. This can lead to unexpected failures. Take time to reflect on past experiences with different impellers. Learning from mistakes can guide your selection process.

Identifying Maintenance and Replacement Needs for Longevity

When it comes to rubber pump impellers, maintenance is key for longevity. Inspect them regularly. Look for signs of wear, such as cracks or discoloration. These are indicators that it might be time for a replacement. Don't wait until it breaks down completely. A small crack can quickly lead to bigger issues.

Watch for unusual noises during operation. Squeaking or grinding sounds can signal that your impeller is wearing out. Neglecting these sounds often leads to costly repairs. Cleaning the impeller periodically keeps it functioning optimally. Dirt and debris can cause friction, leading to premature failure.

Consider the operational environment, too. If the pump runs in harsh conditions, more frequent checks are necessary. For instance, the presence of chemicals or solids can accelerate wear. Reflect on your maintenance routines. Are they frequent enough? Adapt as needed to extend the life of your impeller and ensure smooth operation.

Article Source:

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry