- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

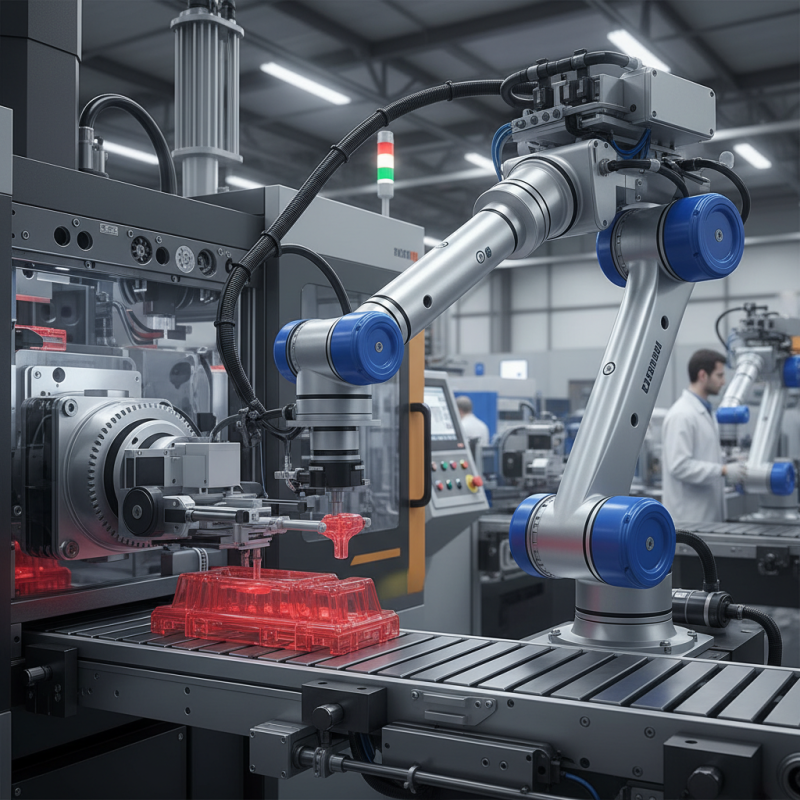

Top Tips for Choosing the Right Injection Machine Robot?

Choosing the right Injection Machine Robot is crucial for efficiency and productivity in manufacturing. John Smith, a leading expert in robotic automation, emphasizes, "Selecting the right robot can make or break your production line." This statement resonates deeply in today’s competitive market.

When considering an Injection Machine Robot, various factors come into play. Users should assess payload capacities, precision requirements, and speed. Often, companies invest heavily in the latest technology only to overlook critical aspects. A mismatch can lead to inefficiencies and higher operational costs.

Moreover, industry needs are evolving. Companies may struggle to keep up with rapid changes in product demands. Consulting with industry professionals can provide valuable insights. A well-informed decision is essential, as the choice of an Injection Machine Robot can significantly impact production. Understanding both the advantages and limitations is key to optimizing performance and ensuring long-term success.

Factors to Consider When Selecting an Injection Machine Robot

Choosing the right injection machine robot involves various essential factors. One key aspect is payload capacity. Robots need to handle the weight of the molds and materials effortlessly. Check the specifications carefully. The size of the working area is another consideration. Too small a workspace can hinder productivity. Assess your factory layout before deciding.

Speed and precision are critical. A robot that works too slowly might affect production rates. However, excessive speed can lead to errors. Balancing these features is necessary. Also, consider the ease of programming. Complicated interfaces can result in longer training times, which is a cost factor. Don't overlook compatibility with existing systems. This could complicate integration and increase downtime.

Maintenance requirements can also vary significantly between models. Some might demand regular calibrations, while others are low-maintenance. Reflect on the team’s skill set. If technicians are inexperienced, a user-friendly machine is ideal. Lastly, evaluate the support services available. Poor after-sales service can lead to significant headaches down the line. Make informed choices to minimize regrets later.

Top Tips for Choosing the Right Injection Machine Robot

Types of Injection Machine Robots and Their Applications

When selecting the right injection machine robot, it’s essential to consider various types and their applications. Articulated robots are popular in this field. They offer flexibility and precision. These robots can perform intricate movements for complex shaping tasks. They are ideal for automotive parts and high-accuracy applications.

Cartesian robots are another choice. They are straightforward and cost-effective. With linear movements, they work well in pick-and-place operations. They excel in straightforward tasks but may lack flexibility. They are often used in packaging and assembly lines.

Delta robots are swift and efficient. They can handle lightweight parts quickly. However, their reach is limited compared to articulated ones. They are often seen in food packaging or electronic assembly. The choice of robot should align with specific production needs and limitations in processes. Make sure to reflect on each type’s strengths and weaknesses.

Assessing Production Needs and Future Scalability

Assessing production needs is essential when choosing an injection machine robot. Begin by evaluating your current manufacturing output. How many parts do you produce daily? Understanding this helps determine the machine's capacity. Consider your workspace as well. A large, cumbersome robot may not fit in a compact facility. Space constraints can hinder operations.

Future scalability is a critical factor too. Businesses change and grow. Will your production needs increase in the next few years? It’s wise to invest in a machine that can adapt. Flexible robots can handle varying tasks and sizes. However, these models may come with a learning curve. Staff training is necessary, and that takes time.

Keep in mind that not every feature will suit your needs. Some machines have advanced capabilities that you might never use. Balancing costs with functionality is tough. Overestimating your needs may lead to waste. It's essential to reflect on your production goals as you make decisions. Ultimately, ensuring you choose a machine that aligns with both present and future requirements is crucial for sustained success.

Top Tips for Choosing the Right Injection Machine Robot

| Criteria | Description | Importance Level | Future Scalability |

|---|---|---|---|

| Production Rate | Determine the required output per hour to meet production goals. | High | Ensures the machine can handle increased demand. |

| Robot Payload | Evaluate the weight of parts to be handled by the robot. | Medium | Allows for upgrades or changes in part design. |

| Footprint | Consider the space available for the machine in your facility. | High | Planning for future expansion and layout redesigns. |

| Compatibility | Ensure the robot can integrate with existing machinery. | High | Facilitates seamless upgrades without major overhauls. |

| Technical Support | Access to user support and spare parts is crucial. | Medium | Aids in quick troubleshooting and maintenance. |

| Energy Efficiency | Look for robots that minimize energy consumption. | Medium | Cost savings and sustainability practices. |

Evaluating Cost vs. Performance for Your Budget

Choosing the right injection machine robot can be challenging. Evaluating cost versus performance is crucial for staying within budget. A lower price tag can be tempting, but it may not guarantee quality. Performance features matter, too. A machine with high speed and precision will save time and enhance production quality.

Carefully assess your production needs. If you require high output, an advanced model may pay off in the long run. Consider the initial investment against potential gains. A robot that fails to meet your needs can lead to delays. This ultimately affects your bottom line.

Don’t ignore maintenance costs. Some machines may require frequent servicing, which adds up. Think about training your staff. Sometimes, complex machines can complicate operations. Weigh these factors to ensure the robot aligns with your long-term goals. Finding balance can be more challenging than it seems.

Key Features to Look for in Injection Machine Robots

When selecting an injection machine robot, certain key features stand out. Accuracy is crucial. Look for machines that offer precise positioning. This ensures consistent quality in production. Repeatability is just as important. A reliable robot should perform the same task with minimal deviation over time.

Speed can significantly impact productivity. Evaluate the robot’s cycle time. A faster cycle time often leads to higher output. However, speed shouldn't compromise accuracy. Some machines may operate quickly but lack precision. Balance is key. Consider the robot's payload capacity. This affects the types of molds it can handle.

Integration with existing systems is another factor. Ensure compatibility with your current setup. Poor integration can lead to delays and increased costs. Many choose robots based solely on features. But sometimes, these features don’t align with actual production needs. Reflect on your specific requirements. Tailor your choice to match the demands of your operation for better outcomes.

Article Source:

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry