- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

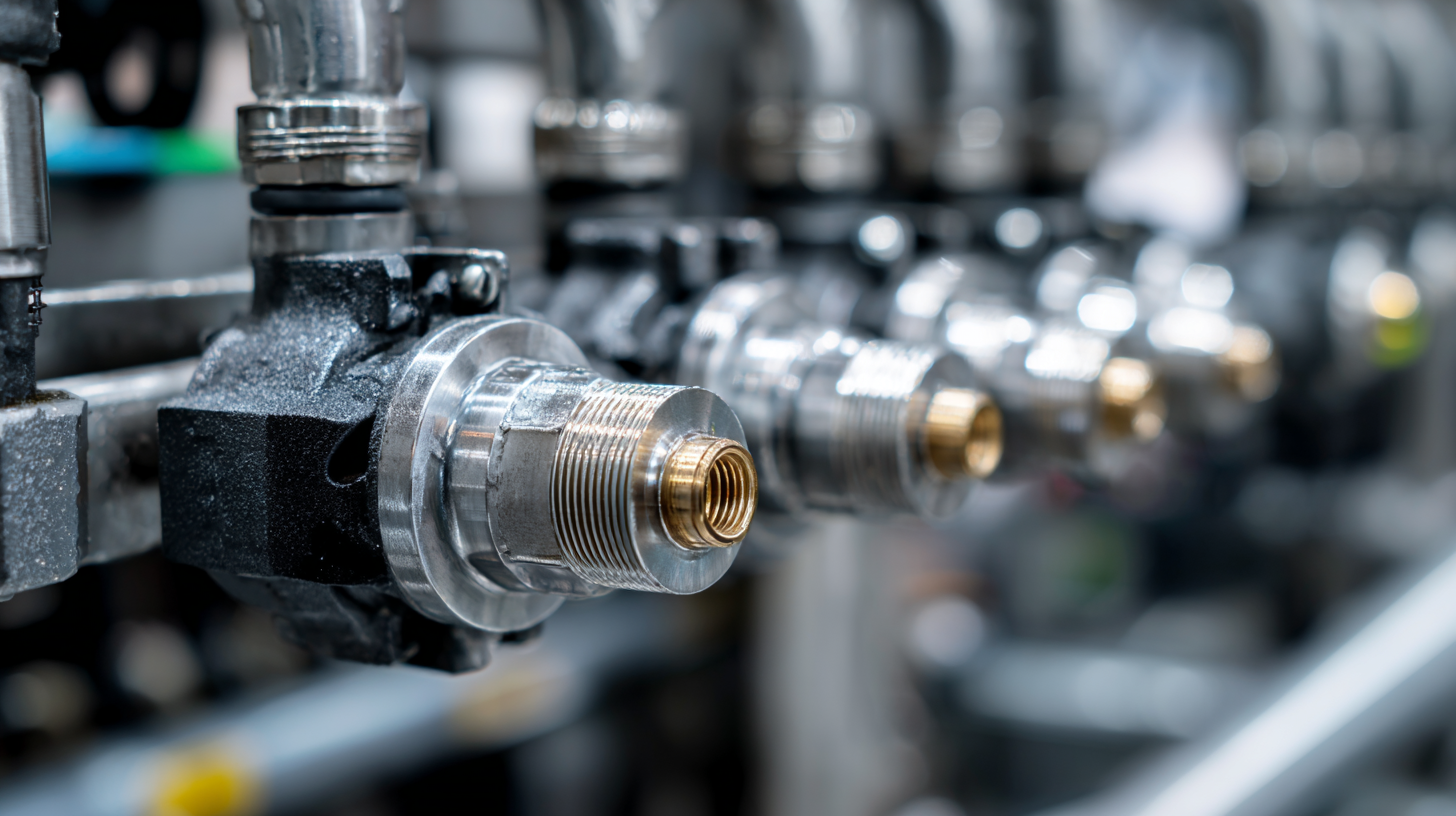

Understanding the Essential Role of Industrial Hose Fittings in Modern Manufacturing Processes

In the realm of modern manufacturing, the significance of Industrial Hose Fittings cannot be overstated. These essential components serve as the connective tissue within various systems, facilitating the efficient transfer of fluids and gases necessary for operational success. As industries increasingly prioritize efficiency, safety, and reliability, understanding the role of these fittings becomes crucial for engineers and technicians alike. This guide aims to explore the myriad types of industrial hose fittings, offering insights into their applications, selection criteria, and best practices for installation and maintenance. By delving into the intricacies of industrial hose fittings, we equip professionals with the knowledge to enhance their manufacturing processes, ensuring optimal performance and longevity of their equipment.

The Importance of Industrial Hose Fittings in Manufacturing Efficiency

Industrial hose fittings play a crucial role in enhancing manufacturing efficiency by ensuring safe and reliable fluid transfer in various processes. These fittings serve as the connectors between hoses and machinery, enabling the seamless flow of liquids, gases, or slurries. In modern manufacturing environments, where precision and performance are paramount, the quality of hose fittings directly impacts overall operational productivity. Well-designed fittings reduce the likelihood of leaks, which can lead to equipment damage, safety hazards, and costly downtime.

Moreover, the adaptability of industrial hose fittings contributes to greater manufacturing flexibility. With a wide range of configurations and materials available, these fittings can be tailored to meet specific operational needs across different industries. This versatility allows manufacturers to quickly adapt to changing production demands and maintain efficiency in increasingly competitive markets. As businesses strive to optimize their operations, investing in high-quality industrial hose fittings becomes an essential component of their strategic approach to enhancing productivity and ensuring sustainable growth.

Understanding the Essential Role of Industrial Hose Fittings in Modern Manufacturing Processes - The Importance of Industrial Hose Fittings in Manufacturing Efficiency

| Fitting Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Applications |

|---|---|---|---|---|

| Eagle Coupling | Aluminum | 300 | -40 to 150 | Hydraulic Lines |

| Industrial Clamp | Stainless Steel | 500 | -30 to 200 | High Pressure Applications |

| Quick Disconnect | Brass | 250 | -20 to 180 | Air and Fluid Transfer |

| Barbed Fitting | Polypropylene | 150 | 0 to 160 | Chemical Processing |

| Pipe Fitting | PVC | 200 | 32 to 140 | Water Supply |

Key Features to Look for in Industrial Hose Fittings

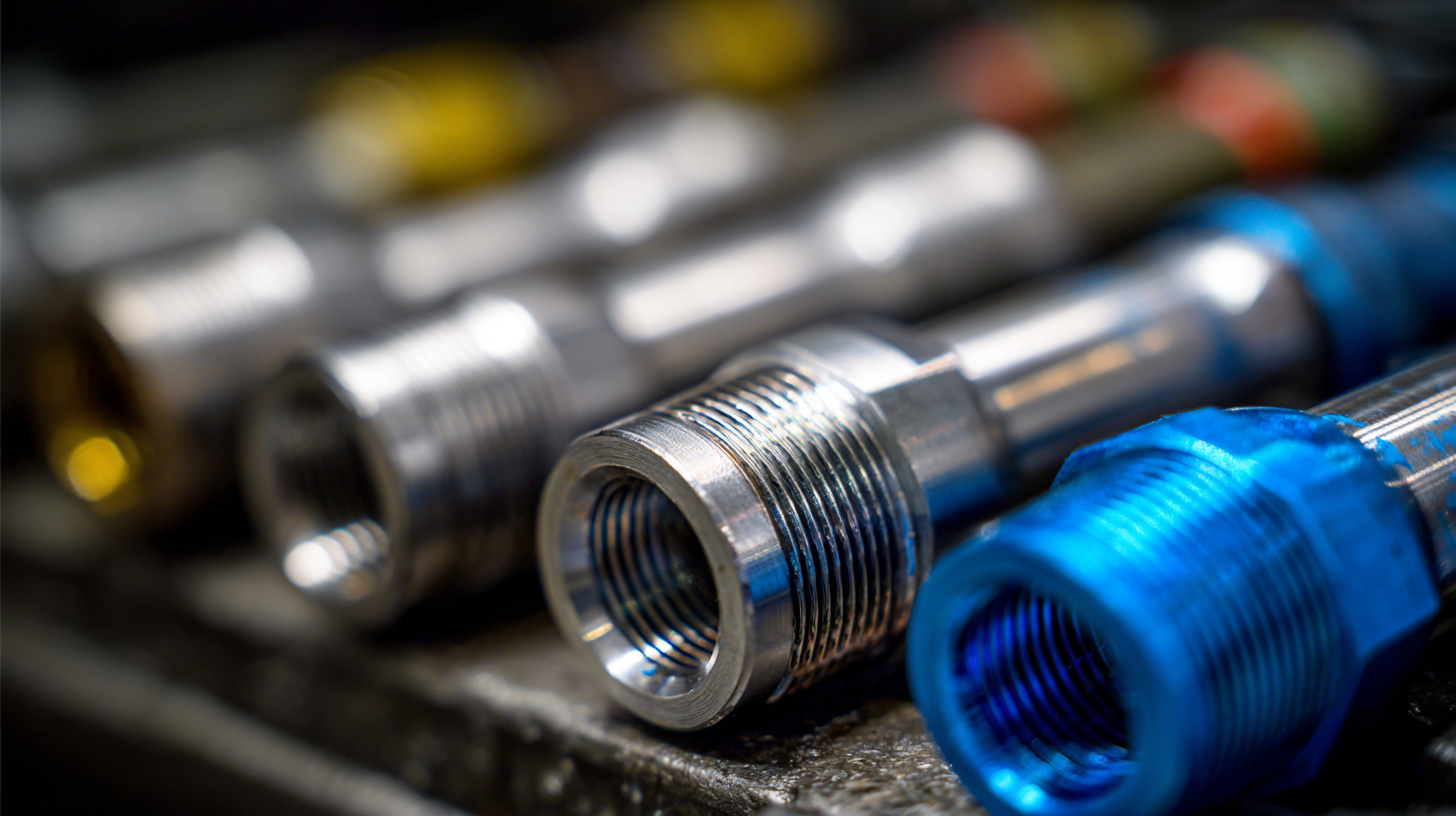

Industrial hose fittings play a vital role in ensuring the efficiency and safety of modern manufacturing processes. When selecting these fittings, several key features are essential. First and foremost, material compatibility is crucial; fittings made from high-quality materials such as stainless steel or brass can withstand harsh environments and resist corrosion. According to a report by the Industrial Hose Association, approximately 70% of hose failures can be attributed to improper fitting materials, highlighting the importance of choosing the right options for specific industrial applications.

Another critical feature to consider is the fitting's pressure rating. The ability to withstand high pressures is indispensable in environments where fluid transfer occurs under significant stress. Manufacturers should look for fittings that meet or exceed the required pressure standards for their operations. A 2022 market analysis revealed that businesses utilizing appropriately rated fittings saw a 25% reduction in unexpected downtime due to equipment failure. Additionally, ease of installation and maintenance should not be overlooked; quick-connect fittings can significantly reduce operational interruptions, further optimizing manufacturing efficiency in a competitive marketplace.

Common Types of Industrial Hose Fittings and Their Applications

Industrial hose fittings are critical components in modern manufacturing processes, enabling efficient fluid transport and connectivity across various systems.  These fittings come in several types tailored for specific applications, ensuring their optimal performance in handling different materials and pressures. Common types include hydraulic hose fittings, which are essential for transferring hydraulic fluids in machinery, and pneumatic fittings, which facilitate the transport of compressed air in industrial settings. The rising demand for these products highlights their importance in sectors such as automotive, construction, and manufacturing.

These fittings come in several types tailored for specific applications, ensuring their optimal performance in handling different materials and pressures. Common types include hydraulic hose fittings, which are essential for transferring hydraulic fluids in machinery, and pneumatic fittings, which facilitate the transport of compressed air in industrial settings. The rising demand for these products highlights their importance in sectors such as automotive, construction, and manufacturing.

Tip: When selecting hose fittings, always consider the operating conditions, such as pressure and temperature, as well as the compatibility with the fluid being conveyed. Ensuring the right fit can prevent leaks and system failures.

Moreover, with the global market for hydraulic hose fittings projected to grow significantly in the coming years, manufacturers are focusing on innovation and quality to meet rising industry standards. The transition toward more efficient fluid conveyance systems allows for improved productivity and safety across manufacturing processes.

Tip: Regularly inspect and maintain hose fittings to ensure their integrity and performance. This proactive approach can help prevent unexpected downtimes and costly repairs.

Maintenance Tips for Extending the Life of Hose Fittings

Maintaining the longevity of industrial hose fittings is crucial for ensuring optimal performance in manufacturing processes. Regular inspection is the first step in this maintenance regimen. Operators should routinely check for signs of wear, corrosion, or damage to fittings, as these can lead to leaks or system failures. Additionally, ensuring that the fittings are properly tightened can prevent unnecessary wear and prolong their usable life.

Lubrication is another key factor in extending the life of hose fittings. Using the appropriate lubricant helps reduce friction and wear between the mating surfaces, which can enhance the overall efficiency of the system. Furthermore, operators should be mindful of the working environment; exposure to harsh chemicals or extreme temperatures can significantly degrade the materials. By implementing these simple yet effective maintenance tips, manufacturers can avoid costly downtime and ensure that their operations run smoothly.

Industrial Hose Fittings Maintenance: Impact on Longevity

Troubleshooting Common Issues with Industrial Hose Fittings

In the realm of modern manufacturing, industrial hose fittings play a pivotal role in ensuring efficient operations. However, issues such as leaks and damage can severely impact productivity. According to recent industry data, approximately 30% of unscheduled downtime in manufacturing facilities is attributed to equipment failures, including those caused by faulty hose fittings. Understanding these common pitfalls can help manufacturers avoid costly interruptions.

One common issue is the improper installation of hose fittings, which often leads to leaks. To mitigate this, ensure that all fittings are compatible with the hoses used and follow the manufacturer’s installation guidelines diligently. Regular inspection of fittings can also help catch potential problems before they escalate.

Tips: Always confirm the material compatibility of fittings with the fluids being transported. Additionally, investing in quality fittings might seem costlier upfront but can lead to significant savings by reducing maintenance costs and downtime in the long run. Furthermore, consider using expandable hoses, which offer flexibility and reduce the risk of tangling or kinking, thus prolonging the lifespan of both hose and fittings.

Related Posts

-

Maximizing Efficiency and Minimizing Cost: The Role of Aftermarket Support in Industrial Hose Fittings

-

Hydraulic Fittings Showcase Success at the 137th Canton Fair Set to Drive International Trade Growth

-

Exploring Innovative Alternatives for Optimal Industrial Hose Fittings

-

7 Innovative Uses for Hydraulic Hoses in Industrial Applications

-

What is the Importance of Industrial Hose Fittings in Global Supply Chains

-

“Unveiling the Best Gates Hoses: Industry Standards and Global Sourcing Insights for Buyers”

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry