- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

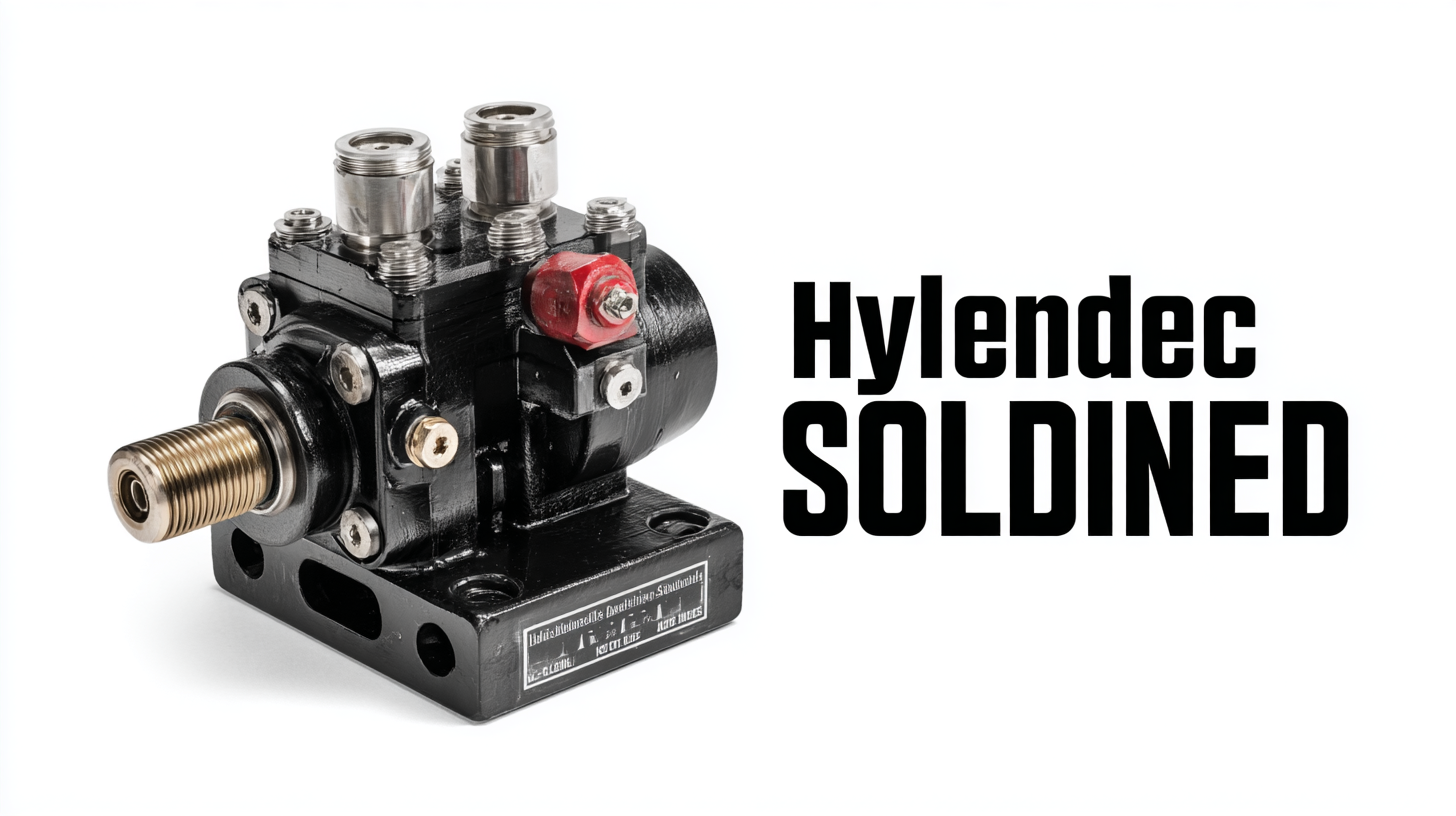

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

The Future of Best Hydraulic Solenoids: Innovations Driving Industrial Efficiency

In the rapidly evolving landscape of industrial automation, Hydraulic Solenoids are poised at the forefront of innovation, driving efficiency and performance across various sectors. These essential components, known for their ability to control the flow of hydraulic fluids, are becoming increasingly sophisticated, adapting to the demands of modern machinery and processes. From their fundamental role in automotive systems to applications in manufacturing, construction, and beyond, the distinct characteristics and suitability of different types of hydraulic solenoids are crucial for optimizing operational effectiveness. As we delve into the future of these technologies, we will explore the innovations that are transforming hydraulic solenoids, ensuring they not only meet the current industry standards but also pave the way for enhanced functionality and sustainability in industrial settings.

Key Factors to Consider When Choosing a Hydraulic Solenoid Manufacturer

When selecting a hydraulic solenoid manufacturer, there are several key factors that industry professionals must consider to ensure optimal performance and reliability in their applications. First and foremost, it's essential to evaluate the manufacturer's experience and expertise in producing hydraulic components. A company with a solid track record is more likely to understand the specific requirements of your industry and offer tailored solutions that enhance efficiency.

Another important consideration is the quality of materials and technologies utilized in the manufacturing process. The best manufacturers invest in high-quality materials that can withstand demanding environments and offer durability over time. Furthermore, innovative technologies such as automation and advanced testing procedures can significantly impact the reliability of the solenoids. Manufacturers that prioritize research and development are more likely to provide products equipped with the latest advancements, ensuring improved performance and cost-effectiveness.

Lastly, considering customer support and service is crucial. A responsive manufacturer that provides comprehensive technical support and guidance can help streamline the selection and installation processes, leading to long-term satisfaction. Choosing a hydraulic solenoid manufacturer who prioritizes collaboration and customer feedback can ultimately lead to improved operational efficiency and stronger partnerships in the long run.

Understanding Industry Standards for Hydraulic Solenoid Performance

The performance of hydraulic solenoids is increasingly governed by stringent industry standards that aim to ensure efficiency and reliability in various applications. According to a recent report by the Institute for Hydraulic Innovation, compliance with ISO 4400 standards can enhance solenoid response times by up to 30%, maximizing operational efficiency. These standards encompass critical factors such as electromagnetic compatibility, temperature tolerance, and lifecycle durability. As industries seek to improve throughput and minimize downtime, the adoption of these performance benchmarks is vital.

Moreover, manufacturers are now focusing on innovations that align with emerging industry standards. For instance, advancements in materials and design have led to the development of solenoids that not only meet but exceed traditional performance metrics. A case in point is the use of high-temperature-resistant polymers that extend the lifespan of solenoids in demanding environments. According to a study published by the Hydraulic Engineering Society, solenoids incorporating these materials can achieve a mean time between failures (MTBF) exceeding 50,000 hours, which is a significant improvement over earlier models. As these innovations continue to reshape the hydraulic sector, adherence to established performance standards will remain critical for industry leaders aiming to push the boundaries of operational excellence.

Evaluating Innovations in Hydraulic Solenoid Technology

The advancement of hydraulic solenoid technology is pivotal in enhancing industrial efficiency. Recent reports indicate that the global hydraulic solenoid market is projected to grow at a CAGR of 5.4% from 2021 to 2028, driven by the increasing demand for automation in various sectors. Innovations such as proportional solenoids are gaining traction for their ability to provide precise control over fluid flow. This precision not only boosts operational efficiency but also minimizes energy consumption, an essential factor in sustainable industrial practices.

To ensure you are leveraging the latest in hydraulic solenoid technology, here are some tips: First, consider integrating proportional solenoids into your existing systems; their adaptability can significantly reduce operational costs. Additionally, staying updated with industry advancements through reports and trade publications can help you identify emerging technologies that offer competitive advantages. Finally, regular maintenance and calibration of hydraulic systems can extend the life of solenoids and maintain optimal performance, ensuring long-term operational efficiency.

As industries evolve, it is essential to evaluate the technologies that support these transformations. Hydraulic solenoids, with their innovative designs and enhanced capabilities, are crucial in driving productivity and efficiency across multiple sectors.

The Future of Best Hydraulic Solenoids: Innovations Driving Industrial Efficiency

| Innovation Area | Description | Efficiency Improvement (%) | Expected Adoption Year |

|---|---|---|---|

| Smart Sensors | Integration of IoT sensors for real-time monitoring and performance analytics. | 25% | 2025 |

| Advanced Materials | Use of lightweight, durable materials to reduce wear and improve longevity. | 15% | 2024 |

| Electromagnetic Efficiency | Enhanced electromagnetic designs for lower energy consumption. | 30% | 2026 |

| AI Optimization | Application of AI algorithms for predictive maintenance and operational efficiency. | 40% | 2027 |

| Modular Designs | Designs that allow easy upgrades and customizations without full replacement. | 20% | 2023 |

Comparative Analysis of Top Hydraulic Solenoid Brands

The hydraulic solenoid market is witnessing significant innovations aimed at improving industrial efficiency. With the growing demand for precision and control in fluid management systems, a comparative analysis of leading hydraulic solenoid brands reveals key trends influencing their design and functionality. Recent reports indicate that the industrial valve market, which encompasses various types including solenoid valves, is projected to reach a considerable value by 2026, driven by the expanding applications in sectors such as oil and gas, water treatment, and manufacturing.

Leading brands are incorporating advanced materials and smart technologies into their design processes, enhancing the durability and responsiveness of hydraulic solenoids. A study highlighted that the adoption of automation and IoT technologies in industrial applications is expected to boost the demand for solenoid valves, with some segments reporting growth rates of up to 5.2% annually. This acceleration not only underscores the competitive landscape among manufacturers but also emphasizes the importance of efficiency and energy savings as critical differentiators in product offerings.

Evaluating top brands reveals a focus on sustainable practices and innovative solutions that cater to specific industry needs. With ongoing research and development, the hydraulic solenoid market is set to evolve, further integrating cutting-edge technologies that streamline operations and reduce environmental impact. This comparative analysis sheds light on how innovation remains at the forefront of driving growth and efficiency in the industrial sector.

Impact of Quality Manufacturing on Industrial Efficiency and Reliability

In today's competitive industrial landscape, the impact of quality manufacturing on hydraulic solenoids cannot be overstated. According to a recent report from the Freedonia Group, the demand for hydraulic components, including solenoids, is projected to reach $12 billion by 2026, driven largely by advances in manufacturing technology. High-quality production methods not only enhance the longevity and reliability of these components but also contribute to overall operational efficiency. Manufacturers that prioritize precision engineering and rigorous quality control in their solenoid production are seeing a significant reduction in failure rates, which can lead to costly downtimes.

Moreover, a study by the International Organization for Standardization (ISO) highlights that effective quality management systems can improve not just product quality but also operational performance. Companies that implement rigorous testing protocols and utilize advanced materials report a marked increase in their equipment's reliability. By investing in superior manufacturing practices, industries can streamline processes and minimize waste, effectively driving productivity. In this evolving landscape, the correlation between high-quality hydraulic solenoids and sustained industrial efficiency is becoming increasingly evident, setting new standards for operational excellence.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry