- Home Page

- Company Profile

-

Our Products

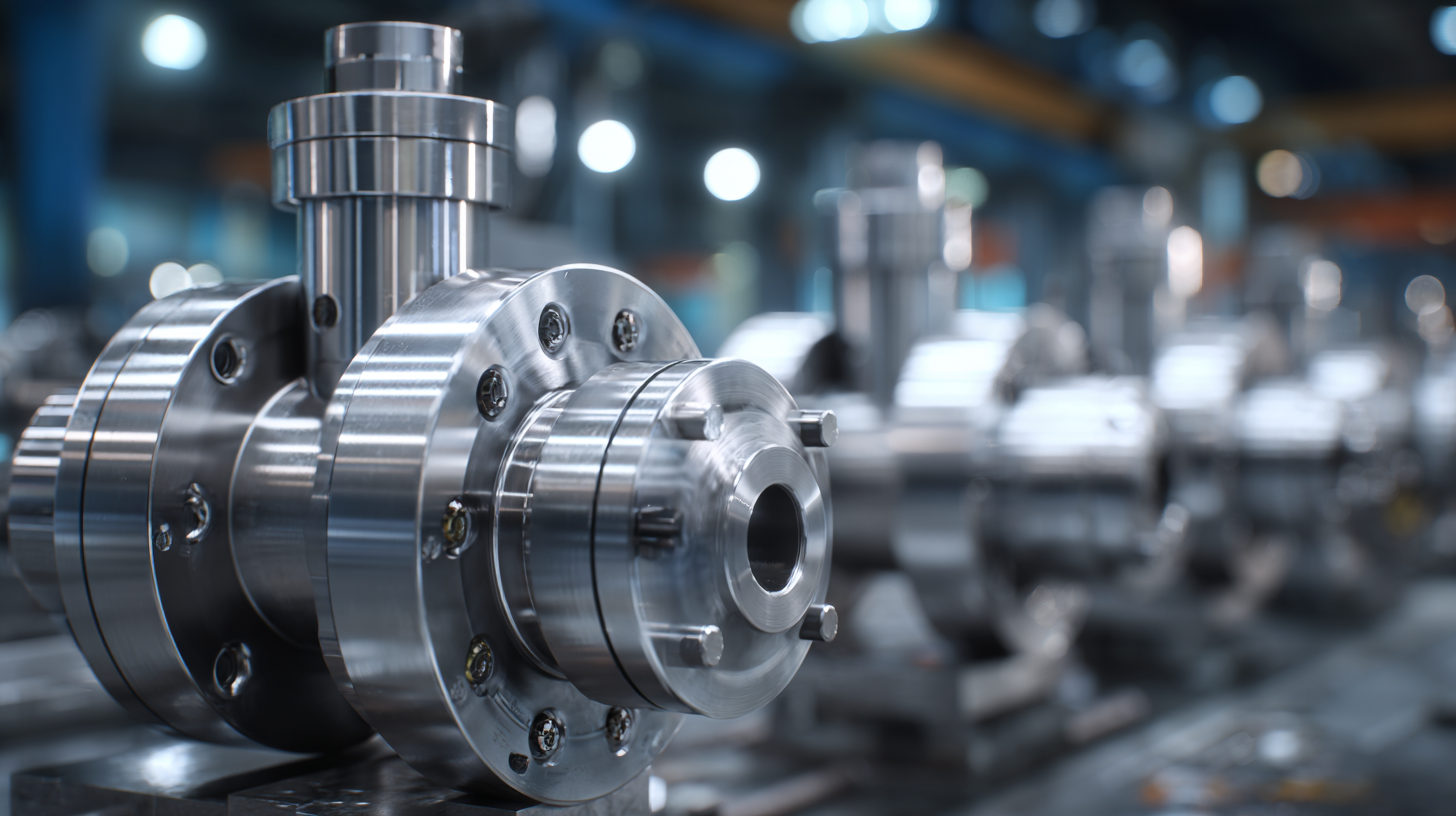

- Hydraulic Pumps

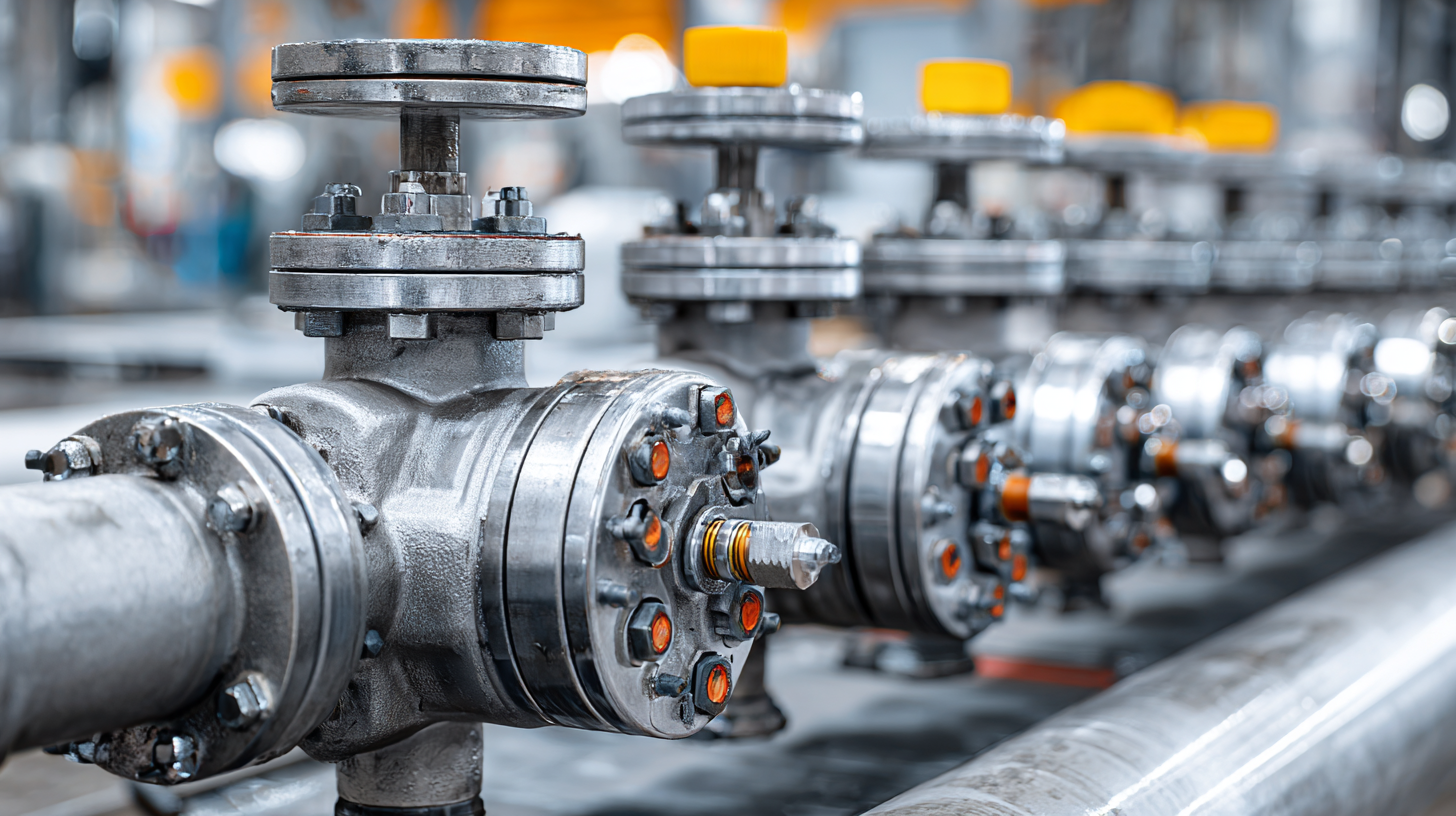

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

Exploring the Future of Best Industrial Valves in Industry 2025 Technology Trends

As we approach 2025, the landscape of industrial valves is poised for significant transformation, driven by technological advancements and evolving industry demands. According to a recent report by MarketsandMarkets, the global industrial valves market is projected to reach USD 85 billion by 2025, growing at a CAGR of 6.1% from 2020. This surge reflects not only the increasing need for efficient fluid control systems in various sectors, including oil and gas, water and wastewater management, and chemical processing, but also emphasizes the uncompromising focus on quality that has become synonymous with “Made in China.”

As China continues to enhance its manufacturing capabilities, it is setting a benchmark for quality that garners respect globally, positioning its industrial valves as reliable solutions in the face of stringent international standards. In this blog, we will delve into the future of industrial valves, exploring the innovative technologies shaping the industry and their potential impact on global markets.

As China continues to enhance its manufacturing capabilities, it is setting a benchmark for quality that garners respect globally, positioning its industrial valves as reliable solutions in the face of stringent international standards. In this blog, we will delve into the future of industrial valves, exploring the innovative technologies shaping the industry and their potential impact on global markets.

The Rising Demand for Industrial Valves: Global Market Projections for 2025

The industrial valve market is anticipated to experience significant growth by 2025, driven by the rising demand across various sectors, including oil and gas, water treatment, and chemical processing. Industry experts predict that advancements in technology will further enhance the efficiency and functionality of these valves, catering to evolving industrial requirements. Furthermore, with increasing environmental regulations, the need for reliable and efficient valves has never been more pressing, prompting manufacturers to innovate relentlessly.

**Tip:** When selecting industrial valves, consider not only the material and design but also the valve's compatibility with your specific application. Ensuring that the valve meets industry standards will help minimize operational disruptions and maintenance costs over time.

As the global market for industrial valves expands, companies must stay informed about emerging trends and technologies that could affect their operations. Trends such as automation and IoT integration are transforming how valves are monitored and controlled, enhancing overall system reliability. Companies that adapt to these changes early will likely gain a competitive edge in the market.

**Tip:** Regularly evaluate your current valve inventory and consider adopting smart valves equipped with sensors. These innovations can provide real-time data, enabling proactive maintenance and ensuring peak performance while reducing downtime.

Industrial Valves Market Projections for 2025

The following bar chart illustrates the projected growth in demand for various types of industrial valves across different sectors by 2025. The data reflects an increasing trend, driven by advancements in technology and a rising focus on automation.

Innovative Technologies Revolutionizing Valve Manufacturing: A 2025 Perspective

The future of industrial valves is set to be dramatically transformed by innovative technologies as we approach 2025. With the global butterfly valves market projected to reach USD 11.7 billion, a CAGR of 6.5% indicates significant growth opportunities. This expansion will likely be fueled by advancements in manufacturing practices, particularly the integration of AI and 3D printing. AI stands at the forefront, optimizing factory operations to reduce costs and enhance sustainability, allowing manufacturers to respond more effectively to market demands.

As we explore the innovations in valve manufacturing, it's essential to consider how emerging technologies can improve production processes. For instance, incorporating 3D printing could streamline the creation of complex valve components, enabling customization and quicker turnaround times.

**Tips for Industry Leaders**: To stay ahead, companies should invest in training their workforce on these new technologies. Emphasizing a culture of continuous learning will position them to quickly adapt as the industry evolves. Additionally, exploring partnerships with innovative startups can provide new insights and collaborative opportunities that drive progress in valve manufacturing. Driving forward with these technologies will not only enhance efficiency but also redefine product quality in the industrial sector.

Exploring the Future of Best Industrial Valves in Industry 2025 Technology Trends

| Technology Trend | Expected Impact | Implementation Year | Key Advantages |

|---|---|---|---|

| Smart Valve Technology | Improved monitoring and control | 2025 | Increased efficiency and reduction of downtime |

| 3D Printing | Cost reduction in manufacturing | 2025 | Customization and shorter lead times |

| IoT Integration | Enhanced data analytics capabilities | 2025 | Real-time monitoring and predictive maintenance |

| Advanced Materials | Increased durability and performance | 2025 | Resistance to corrosion and lower maintenance costs |

| AI and ML in Valve Design | Optimized designs for performance | 2025 | Reduced R&D time and enhanced product life |

Sustainability Trends in Industrial Valves: Reducing Environmental Impact by 2025

As we look towards 2025, sustainability emerges as a pivotal trend in the industrial valves sector. Manufacturers are increasingly recognizing their responsibility to reduce environmental impact, leading to innovations that prioritize eco-friendly materials and efficient valve designs. By adopting sustainable manufacturing practices, companies can minimize waste and lower their carbon footprint, aligning their operations with global green initiatives.

Moreover, the integration of smart technology in valve systems plays a crucial role in enhancing sustainability. Smart valves equipped with IoT capabilities enable real-time monitoring and optimization of fluid dynamics, resulting in more precise control and reduced resource consumption. This technological advancement not only improves operational efficiency but also promotes the use of renewable energy sources, contributing to a greener industrial landscape.

In addition to technology-driven solutions, collaboration within supply chains is essential for promoting sustainability. By partnering with suppliers who share similar environmental goals, valve manufacturers can enhance their sustainability initiatives and lead the way in creating eco-friendly products. As we approach 2025, the commitment to sustainable practices in the industrial valves sector will be critical in shaping a more environmentally conscious industry.

China's Role in Shaping the Global Valve Industry: Export Statistics and Growth

As we delve into the future of the industrial valve market, China's pivotal role cannot be overlooked. In recent years, China has emerged as a leading player in the global valve industry, significantly boosting its export statistics. Leveraging advanced manufacturing technologies and a vast labor force, Chinese manufacturers are meeting the increasing demand for high-quality, reliable valves. This surge in production not only caters to domestic needs but also establishes China as a major exporter to markets across Asia, Europe, and North America.

The growth trajectory of China's valve exports highlights its strategic investment in innovation and quality control. By implementing cutting-edge production techniques and adhering to international standards, Chinese companies are enhancing their competitive edge. Furthermore, with the integration of smart technologies, such as IoT and AI, into valve manufacturing and monitoring systems, Chinese manufacturers are set to redefine industry standards. This evolution signals a transformative shift in the global valve landscape, suggesting that China's influence will continue to be a driving force in shaping industry trends leading into 2025 and beyond.

Advanced Materials and Their Impact on Industrial Valve Performance by 2025

The evolution of advanced materials is set to revolutionize the performance of industrial valves by 2025. As industries face increasing demands for efficiency, durability, and sustainability, the integration of high-performance materials such as titanium alloys, composite materials, and innovative polymers is essential. These materials offer enhanced resistance to corrosion and wear, extending the lifespan of valves and reducing maintenance costs, which is crucial for operations in harsh environments.

Furthermore, the development of smart materials will play a significant role in the next generation of industrial valves. These materials can adapt to changing conditions, providing real-time feedback and self-regulation capabilities. By harnessing the power of smart technology, manufacturers can design valves that not only optimize flow control but also improve energy efficiency. This shift towards intelligent systems will help industries meet stringent regulatory standards while minimizing their environmental impact, paving the way for a more sustainable future in industrial operations.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry