- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

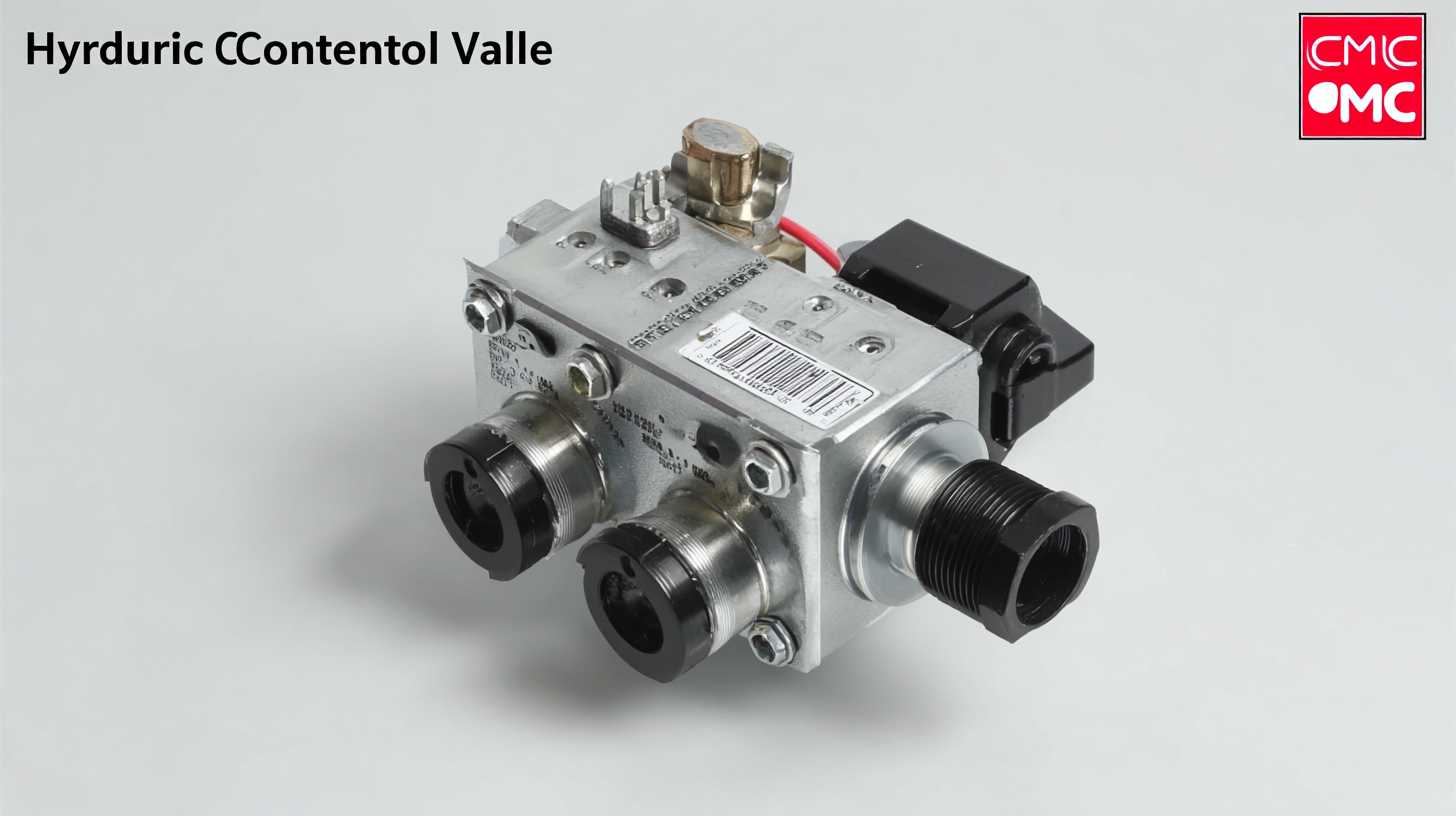

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

How to Identify the Top Manufacturer for Best Hydraulic Control Valves

The demand for Hydraulic Control Valves has surged globally, driven by the expanding industrial and construction sectors. According to a recent market report by Research and Markets, the hydraulic valve market is projected to reach USD 29.66 billion by 2027, growing at a CAGR of 5.1% from 2020 to 2027. This substantial growth highlights the critical role that hydraulic control valves play in enhancing the efficiency and performance of hydraulic systems across various applications, from manufacturing to automotive industries. With numerous manufacturers competing for market leadership, identifying the top producers of hydraulic control valves becomes essential for ensuring quality and reliability. This blog will delve into the key factors that distinguish the best manufacturers in the global market, particularly those recognized for their excellence in producing hydraulic control valves.

Understanding Hydraulic Control Valves: Key Features and Applications

Hydraulic control valves play a critical role in many industrial applications, providing precise control over fluid flow and pressure. Understanding the key features of these valves is essential for selecting the right manufacturer. Key attributes to consider include response time, durability, compatibility with fluid types, and the incorporation of advanced technologies such as proportional valves, which have evolved to meet the demands of more complex applications. These advancements allow for greater connectivity and more precise control, enhancing system performance.

Moreover, ongoing innovations in hydraulic systems, including the integration of sensor technologies for performance monitoring, are pushing the boundaries of traditional hydraulic machinery. Recent developments, such as hybrid actuators that combine electromechanical and hydraulic principles, illustrate how the industry is adapting to the challenges of deep-sea applications and other demanding environments. As hydraulic technology continues to evolve, manufacturers that embrace these innovations and focus on providing enhanced efficiency and reliability will stand out as leaders in the field, ensuring their products meet the needs of modern engineering challenges.

The Importance of Manufacturer Reputation in the Hydraulic Industry

In the hydraulic industry, the reputation of a manufacturer plays a crucial role in ensuring the reliability and performance of hydraulic control valves. According to a report by Market Research Future, the hydraulic valves market is expected to reach USD 17 billion by 2025, with a compound annual growth rate (CAGR) of around 5% during the forecast period. This growth underscores the increasing demand for high-quality hydraulic systems, making it essential to choose a manufacturer whose reputation is backed by industry certifications and customer satisfaction.

Furthermore, a study conducted by Allied Market Research indicates that over 70% of companies prioritize supplier reputation when sourcing hydraulic components. This is largely due to the direct impact a manufacturer's reliability has on system efficiency and safety. Established manufacturers typically have a proven track record of producing high-performance valves that meet stringent industry standards, thereby reducing risks associated with equipment failures. Therefore, investing time in assessing the reputation of potential manufacturers can be pivotal in achieving optimal performance in hydraulic applications.

Top Hydraulic Control Valve Manufacturers by Reputation Score

Analyzing Performance Metrics: What Sets Top Manufacturers Apart

In the competitive landscape of hydraulic control valves, identifying the top manufacturers requires a deep dive into performance metrics that distinguish the leaders from the rest. Key Performance Indicators (KPIs) serve as critical benchmarks in this assessment, reflecting a manufacturer's efficiency, reliability, and innovation capabilities. For instance, metrics like product failure rates, lead times, and customer satisfaction scores can provide insight into a manufacturer’s operational excellence. Recent industry reports indicate that top manufacturers maintain product failure rates well below 2%, showcasing their commitment to quality and reliability.

Furthermore, manufacturers that focus on employee experience tend to outperform their competitors. Companies that foster a tailored and authentic employee experience report significantly higher productivity and engagement levels, directly impacting their overall performance metrics. Data shows that organizations prioritizing employee satisfaction see a 20% increase in operational efficiency. By examining both the quantifiable KPIs and the qualitative aspects of work culture, businesses can pinpoint manufacturers that not only meet industry standards but are also poised for innovative growth in hydraulic control valve production.

Global Market Trends: Demand for Hydraulic Control Valves in 2023

The global hydraulic control valves market is witnessing substantial growth, driven by increasing demand across various sectors. In 2023, the electro-hydraulic servo valve market is valued at approximately $180.51 million, with projections indicating it will reach $214.4 million by 2032, reflecting a compound annual growth rate (CAGR) of 2.5%. This steady growth can be attributed to advancements in automation technology and the rising need for high-precision control in industrial applications.

Additionally, the non-manual segmented ball valve market is experiencing a remarkable expansion, with an estimated market value of $230.91 million in 2023, expected to increase to $247.99 million by 2024 and soar to $452.79 million by 2032. This segment is forecasted to achieve a robust CAGR of 7.4%, further indicating the dynamic shifts within the hydraulic control valve industry due to technological innovations and evolving manufacturing processes.

The servo valve market, categorized by applications such as aerospace, automotive, and industrial automation, emphasizes the diverse use of hydraulic systems across different industries. The ongoing advancements in actuator technologies, including hydraulic, electric, and magnetic options, are set to reshape operational capabilities and efficiencies, making it imperative for manufacturers to remain competitive in this evolving landscape.

Quality Standards and Certification: Ensuring Reliability in Manufacturing

When selecting the top manufacturer for hydraulic control valves, the importance of quality standards and certifications cannot be overstated. These standards serve as essential benchmarks that ensure the reliability and performance of manufactured products. Reliable certification processes, such as ISO 13485 for medical devices or IATF 16949 for automotive components, not only enhance product quality but also build a manufacturer’s credibility in a competitive market. Companies with a strong focus on quality management systems have demonstrated their capacity to meet the stringent demands of modern manufacturing.

Additionally, in the drive for global competitiveness, manufacturers who adopt recognized quality standards are often better positioned for long-term growth. Regions such as the Finger Lakes have shown that harnessing these standards can lead to economic resilience and opportunities for expansion into new markets. By ensuring that their manufacturing processes comply with internationally recognized certifications, businesses can gain consumer trust while minimizing risks associated with poor quality. Thus, evaluating a manufacturer's commitment to quality standards is crucial for those looking to invest in reliable hydraulic control valves.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry