- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

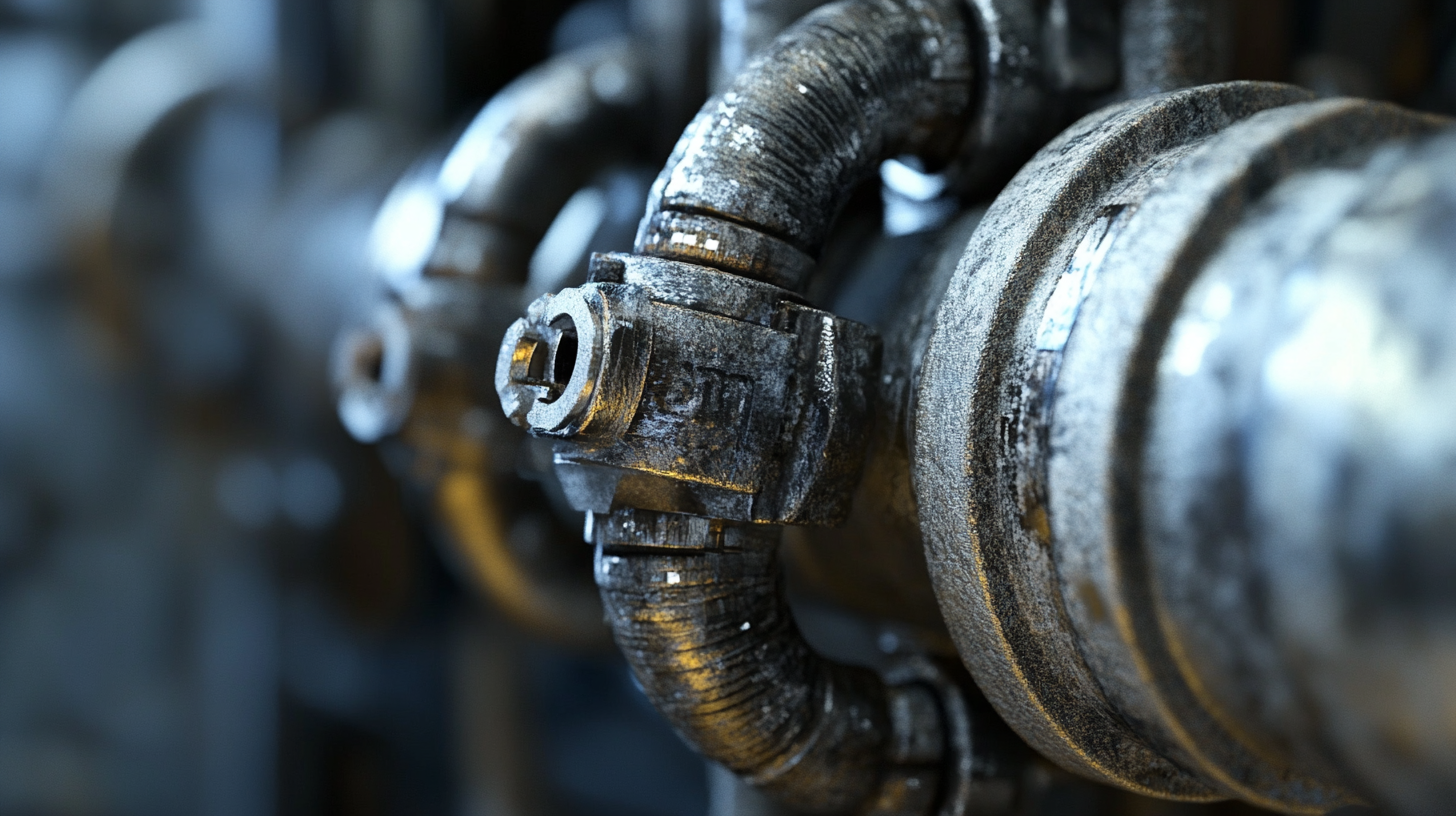

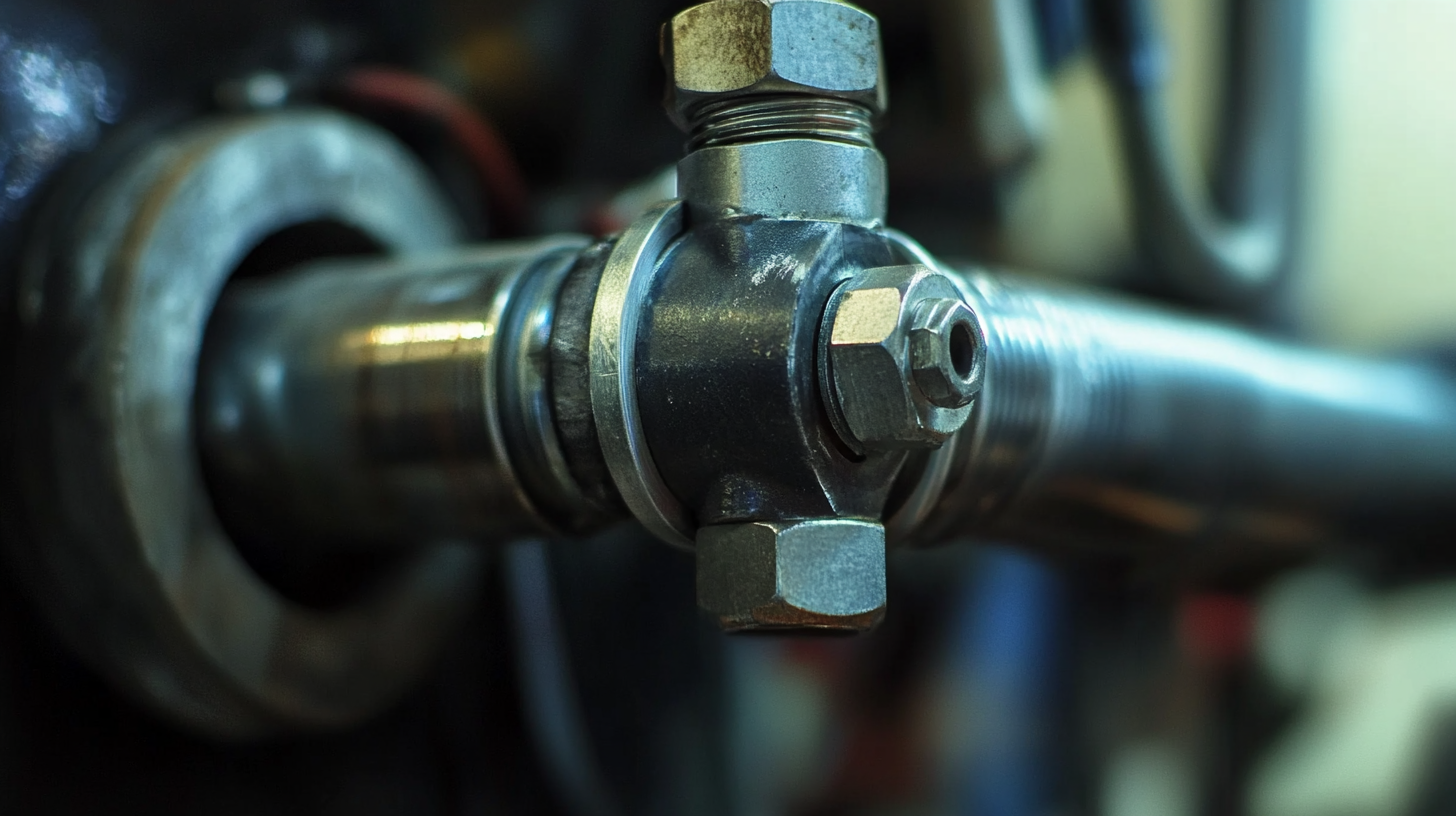

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

Exploring Innovative Alternatives for Optimal Industrial Hose Fittings

In today's fast-evolving industrial landscape, the selection of high-quality industrial hose fittings has never been more critical. As per a recent market analysis by Smithers Pira, the global demand for industrial hose fittings is projected to reach $12 billion by 2025, driven by advancements in manufacturing and increased usage across various sectors including oil and gas, food and beverage, and pharmaceuticals. With the diversity of applications, choosing the right manufacturer and products has become paramount for ensuring safety, reliability, and efficiency in operations. This blog will explore innovative alternatives that not only optimize the performance of industrial hose fittings but also highlight key considerations in selecting premium manufacturers, thereby empowering industry professionals to make informed decisions that enhance operational excellence.

The Evolution of Industrial Hose Fittings: From Traditional to Innovative Solutions

The evolution of industrial hose fittings has seen a significant transformation from traditional materials and designs to innovative solutions that prioritize efficiency, safety, and performance. Traditionally, fittings were primarily made from metal, which, while durable, often posed challenges such as corrosion and weight issues. As industries grew, the limitations of these conventional fittings became apparent, leading to a pressing need for alternatives that could withstand harsher environments while providing ease of use.

In response, manufacturers began exploring advanced materials such as thermoplastics and composites, which offer enhanced resistance to chemicals, temperature fluctuations, and physical wear. These innovative fittings are not only lighter and easier to handle but also designed to minimize leaks and improve flow rates. Additionally, the integration of smart technology into hose fittings is on the rise, allowing real-time monitoring and data collection to optimize performance and maintenance schedules. This shift towards innovation illustrates the industry's commitment to achieving higher standards of safety and efficiency, paving the way for future developments in industrial hose fittings.

Exploring Innovative Alternatives for Optimal Industrial Hose Fittings

This chart illustrates the evolution of industrial hose fittings, showcasing the percentage of usage over the years across different types of fittings, from traditional rubber fittings to innovative alternatives like stainless steel and composite materials.

Key Features of High-Quality Hose Fittings from Leading Chinese Manufacturers

When it comes to industrial hose fittings, quality is paramount, especially for operations that demand reliability and efficiency. Leading Chinese manufacturers have set a high standard by implementing innovative designs and stringent quality controls, producing fittings that not only meet but exceed industry specifications. High-quality hose fittings typically feature materials resistant to abrasion, corrosion, and temperature fluctuations, ensuring durability in various environmental conditions.

Tips for selecting the right hose fittings include assessing compatibility with the existing hoses, considering the pressure ratings, and evaluating the material properties for specific applications. Look for fittings that are designed with ease of installation in mind; this can significantly reduce downtime during replacements or repairs. Additionally, prioritize suppliers who offer comprehensive warranties, as this is often an indicator of their confidence in product performance.

Furthermore, many leading manufacturers focus on providing customizable options to fit unique operational needs. By exploring innovative alternatives, businesses can optimize their systems for both efficiency and safety. Always keep an eye on industry advancements, as technology can lead to the development of more effective and sustainable hose fitting solutions.

Sustainable Practices in the Production of Industrial Hose Fittings

The production of industrial hose fittings has often been criticized for its environmental impact, but

sustainable practices are now at the forefront of

innovation within the industry. By incorporating eco-friendly materials

and processes, manufacturers are reducing their carbon footprint and promoting a

circular economy. For instance, many companies are beginning to

utilize recycled plastics and biodegradable composites as alternatives to traditional materials. This shift

not only minimizes waste but also appeals to environmentally conscious consumers seeking

sustainable options.

The production of industrial hose fittings has often been criticized for its environmental impact, but

sustainable practices are now at the forefront of

innovation within the industry. By incorporating eco-friendly materials

and processes, manufacturers are reducing their carbon footprint and promoting a

circular economy. For instance, many companies are beginning to

utilize recycled plastics and biodegradable composites as alternatives to traditional materials. This shift

not only minimizes waste but also appeals to environmentally conscious consumers seeking

sustainable options.

Furthermore, the adoption of energy-efficient manufacturing technologies plays a crucial role in enhancing sustainability. Techniques like 3D printing and advanced molding not only streamline production but also reduce material waste generated during the fitting creation process. Combining these innovations with sustainable sourcing of raw materials creates a holistic approach to manufacturing that benefits both the environment and the industry.

Emphasizing these practices allows manufacturers to position themselves as leaders in the market while contributing to a greener future.

Exploring the Technological Advancements in Hose Fitting Design and Fabrication

The landscape of industrial hose fittings is undergoing a significant transformation, fueled by rapid technological advancements in design and fabrication processes. Recent reports indicate that the global market for industrial hose fittings is expected to reach $12.5 billion by 2025, driven by the rising demand for sophisticated and durable solutions in various sectors including manufacturing, construction, and oil and gas. Innovative materials, such as advanced polymers and composites, are being utilized to enhance the performance and longevity of hose fittings, enabling them to withstand extreme pressures and corrosive environments.

Furthermore, the adoption of computer-aided design (CAD) and additive manufacturing technologies has streamlined the production of hose fittings, allowing for greater design flexibility and customization. According to a study by MarketsandMarkets, the 3D printing segment is projected to witness a compound annual growth rate (CAGR) of 24.4% through 2027. This technology not only reduces waste but also accelerates the time-to-market for new products. As industries continue to prioritize efficiency and reliability, the evolution of hose fitting design will play a crucial role in meeting the increasing operational demands across various applications.

Global Market Trends: How Chinese Hose Fittings are Gaining International Trust and Adoption

The international market for industrial hose fittings is flourishing, with Chinese manufacturers increasingly gaining a foothold due to their innovative designs and competitive pricing. As global industries seek reliable and efficient solutions, China's advancements in manufacturing technologies have led to the production of high-quality hose fittings that meet rigorous international standards. These products are not only effective in functionality but also reliable in performance, earning the trust of industries worldwide.

Moreover, the adaptability of Chinese hose fittings to various industrial applications—from oil and gas to agriculture—has further amplified their appeal. With a strategic focus on research and development, Chinese companies are introducing advanced materials and precision engineering techniques, enhancing the durability and longevity of their fittings. This commitment to quality ensures that businesses not only reduce operational risks but also optimize their supply chain efficiency. As a result, the acceptance and adoption of Chinese hose fittings continue to rise, signaling a shift in global trust towards innovative manufacturing practices emerging from China.

Exploring Innovative Alternatives for Optimal Industrial Hose Fittings - Global Market Trends: How Chinese Hose Fittings are Gaining International Trust and Adoption

| Region | Market Share (%) | Growth Rate (CAGR %) | Innovative Features | Trust Rating (1-10) |

|---|---|---|---|---|

| North America | 30% | 5% | Lightweight materials, Enhanced flexibility | 8 |

| Europe | 25% | 4% | Corrosion resistance, Higher pressure ratings | 7 |

| Asia-Pacific | 35% | 6% | Eco-friendly materials, Superior durability | 9 |

| Middle East & Africa | 10% | 3% | Temperature resistance, Customizable sizes | 6 |

| Latin America | 5% | 2% | Anti-static properties, Color coding | 5 |

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry