- Home Page

- Company Profile

-

Our Products

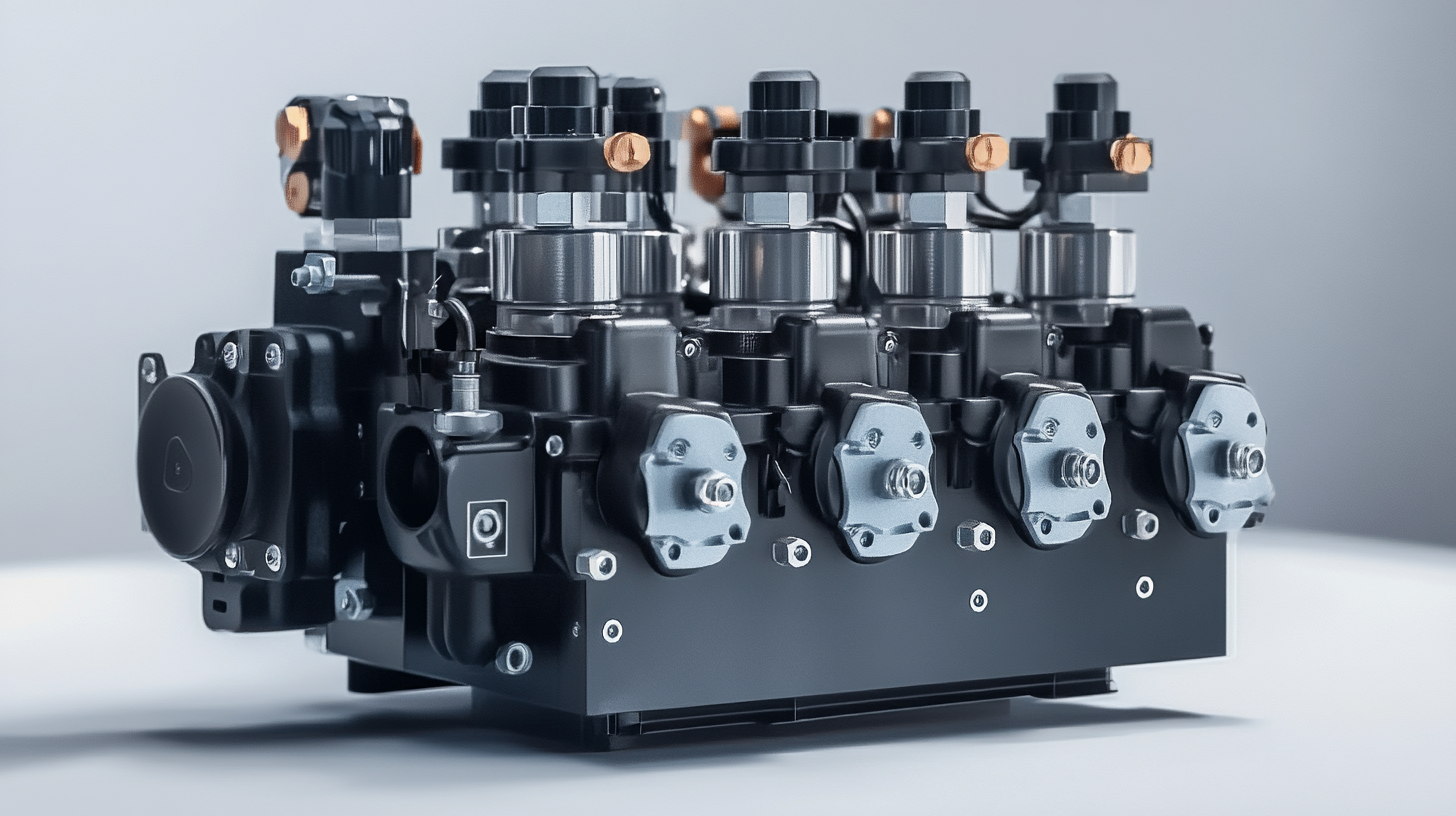

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

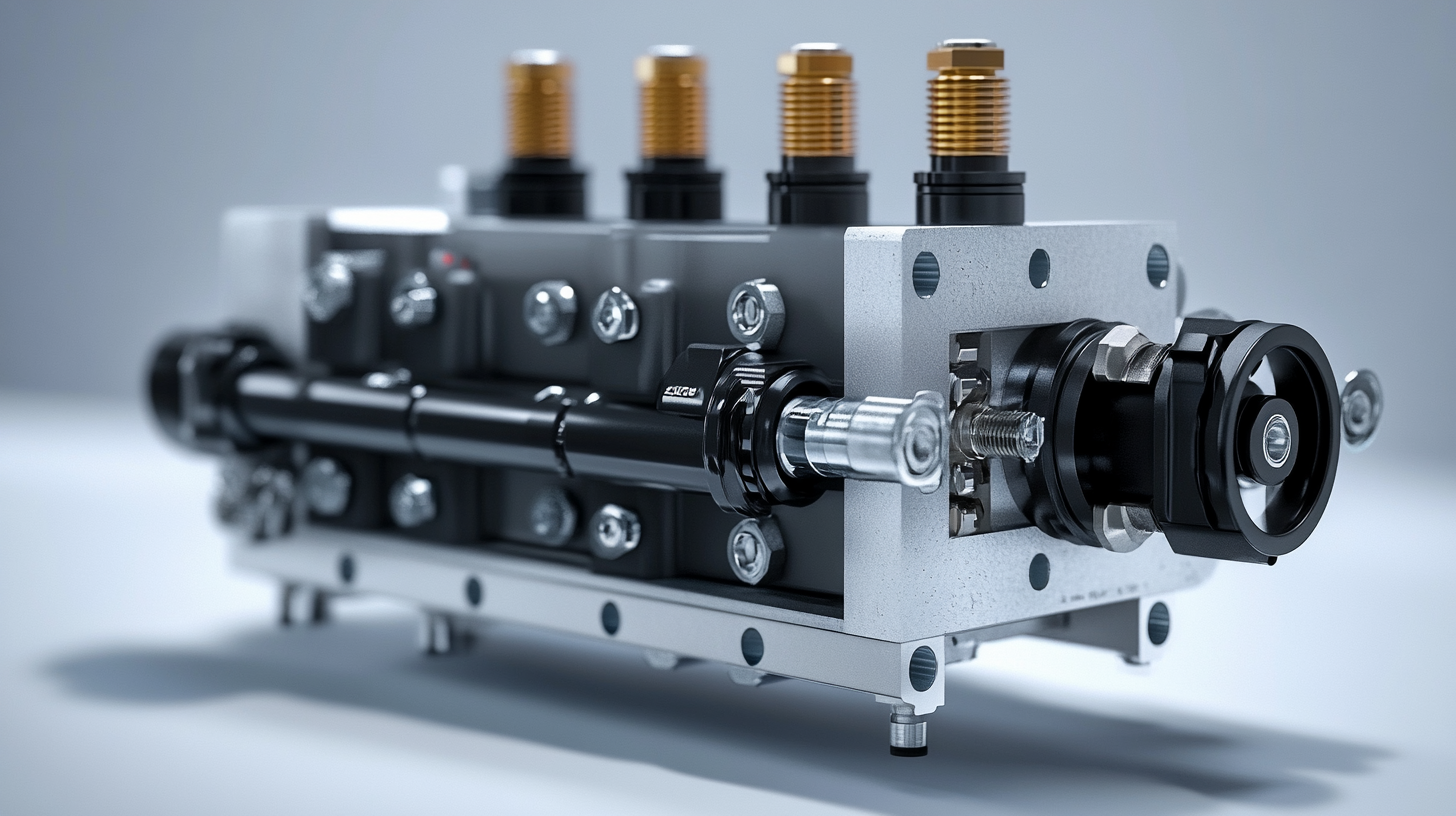

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

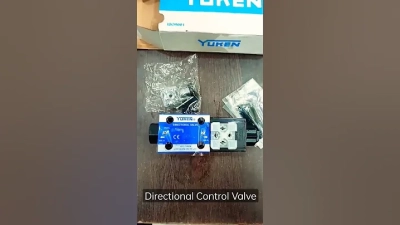

5 Key Advantages of Using Directional Control Valves for Enhanced Hydraulic Efficiency in 2023

In the ever-evolving landscape of hydraulic systems, the significance of **Directional Control Valves** has grown exponentially, underpinning their role in maximizing operational efficiency and system performance. According to a recent report by MarketsandMarkets, the global hydraulic components market is expected to reach $71.1 billion by 2025, with Directly Operated and Pilot Controlled Valves constituting a substantial segment of this sector. This growth can be attributed to the increasing demand for sophisticated machinery in industries such as construction, agriculture, and manufacturing, all of which rely heavily on hydraulic systems for precise control and flexibility.

As the industry embraces advancements in technology, the optimization of fluid control through **Directional Control Valves** is not merely advantageous but essential. These valves facilitate enhanced flow management, reduced energy consumption, and improved response times, addressing the pressing need for sustainability in operations. Furthermore, a study by the International Fluid Power Society indicates that adopting advanced valve systems can lead to efficiency improvements of up to 30%, reflecting the critical nature of these components in achieving both economic and environmental objectives. In light of these insights, this blog explores five key advantages of using Directional Control Valves to bolster hydraulic efficiency in 2023.

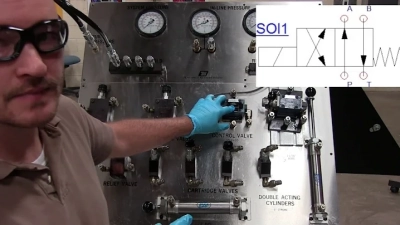

Understanding Directional Control Valves: The Heart of Hydraulic Systems

Directional control valves play a pivotal role in hydraulic systems, serving as the heart that ensures proper fluid routing and effective operation of hydraulically powered machinery. These valves are designed to control the flow of hydraulic fluid, directing it to different actuators and components within the system. According to a report from the Hydraulics and Pneumatics Magazine, approximately 70% of hydraulic system malfunctions are attributed to improper valve selection and usage. This underscores the critical need for understanding and implementing the right directional control valves to maximize system efficiency.

In 2023, advancements in directional control valve technology have led to the development of more precise and reliable systems, enhancing overall hydraulic efficiency. Reports indicate that modern directional control valves, equipped with advanced digital technology, can improve energy efficiency by up to 30%. This shift not only reduces operational costs but also limits environmental impact, aligning with global sustainability goals. The increasing integration of IoT (Internet of Things) into hydraulic systems further amplifies the performance metrics, allowing real-time monitoring and control of the hydraulic processes.

Moreover, the trend towards modular valve systems has gained traction, providing flexibility and scalability to hydraulic designs. According to the International Journal of Fluid Power, modular valve assemblies can reduce installation time by up to 50%, streamlining the manufacturing process and minimizing downtime. The continual evolution of directional control valves is crucial for meeting the diverse demands of various industries, from manufacturing to aerospace, solidifying their status as indispensable components of modern hydraulic systems.

Boosting Efficiency: How Directional Control Valves Optimize Fluid Flow

Directional control valves play a crucial role in optimizing fluid flow within hydraulic systems. By precisely directing the fluid to various components, these valves enhance the overall efficiency of hydraulic operations. In 2023, as industries increasingly focus on improving energy utilization and minimizing waste, the importance of these valves cannot be overstated. They ensure that hydraulic systems operate at peak performance, effectively reducing the energy required to power machinery.

Moreover, the technology behind directional control valves has evolved significantly, introducing features that further streamline fluid management. Advanced designs allow for faster response times and greater accuracy in flow control, which translates into improved performance and responsiveness of hydraulic systems. This optimization not only leads to increased productivity but also helps in reducing operational costs through efficient energy use.

Additionally, directional control valves can be integrated with smart technologies, enabling real-time monitoring and adjustments to fluid flow. This integration provides operators with valuable insights into system performance, allowing for timely interventions and maintenance before issues escalate. As a result, industries can achieve enhanced reliability in their hydraulic systems while also benefiting from increased efficiency. Embracing these advancements in directional control valve technology is essential for any business looking to boost its hydraulic efficiency in today's competitive landscape.

5 Key Advantages of Using Directional Control Valves

Key Features of Directional Control Valves That Enhance Performance

Directional control valves play a pivotal role in optimizing hydraulic systems, offering several key features that greatly enhance performance. One of the primary attributes of these valves is their ability to control the flow direction of hydraulic fluid, facilitating precise operation of machinery and equipment. This key feature allows operators to easily manage the movement of actuators, ensuring that hydraulic power is efficiently directed where it is needed most, which can significantly enhance overall system responsiveness.

Another important aspect of directional control valves is their versatility. They come in various styles, including spools and seat valves, each designed for specific applications. This adaptability enables engineers to choose the right valve configuration to meet their unique operational needs, whether in construction equipment, manufacturing systems, or agricultural machines. Additionally, modern directional control valves are often equipped with advanced control mechanisms, such as proportional and electro-hydraulic controls, which allow for fine-tuning of flow rates and pressure, further improving system efficiency and performance.

Furthermore, the integration of advanced materials and technologies in directional control valves has contributed to their reliability and longevity. Many contemporary models are designed to withstand harsh operating conditions while minimizing wear and tear, leading to reduced maintenance requirements and downtime. The implementation of such robust designs not only enhances the valve's lifespan but also translates into cost savings and improved operational efficiency for businesses that rely heavily on hydraulic systems.

Cost Savings: The Economic Benefits of Improved Hydraulic Efficiency

In 2023, the hydraulic industry continues to thrive, thanks in large part to advancements in technology such as directional control valves. One of the most compelling aspects of these innovations is the significant economic benefits associated with improved hydraulic efficiency. For industries that rely heavily on hydraulic systems, such as oil and gas, construction, and manufacturing, these enhancements can result in substantial cost savings.

Directional control valves optimize fluid flow and reduce energy consumption, allowing companies to operate more effectively. This increased efficiency translates into lower operational costs, which is crucial in a competitive market. Businesses can save on both direct expenses, like energy costs, and indirect ones, such as reduced maintenance and longer equipment lifespan. As seen in the case of hydraulic fracturing, innovations in system efficiency have not only boosted productivity but also helped lower the overall financial barriers associated with resource extraction.

Furthermore, the ability to fine-tune hydraulic operations through advanced valve technology allows for more precise control over the processes, leading to reduced waste and fewer byproducts. In economic terms, this means that companies can allocate their resources more effectively and operate within tighter budget constraints. The continuous push for sustainability also plays a role in this equation, as efficient hydraulic systems often result in a smaller environmental footprint, which can lead to further financial incentives from government bodies and regulatory agencies.

5 Key Advantages of Using Directional Control Valves for Enhanced Hydraulic Efficiency in 2023 - Cost Savings: The Economic Benefits of Improved Hydraulic Efficiency

| Advantage | Description | Cost Impact |

|---|---|---|

| Improved Energy Efficiency | Directional control valves optimize flow and pressure, reducing energy consumption. | Lower utility bills due to reduced energy use. |

| Increased System Reliability | Reliable valves enhance the overall reliability of hydraulic systems. | Reduced downtime leads to cost savings on maintenance. |

| Enhanced Control | Improved operator control over hydraulic functions. | Increased productivity can lead to higher revenue. |

| Cost-effective Maintenance | Modern valves require less frequent replacement and easier servicing. | Saves on parts and labor costs. |

| Versatility in Applications | Can be used in various systems for different applications. | Flexibility can lead to better resource allocation. |

Future Trends: Innovations in Directional Control Valves for 2023 and Beyond

As we move into 2023, the landscape of hydraulic systems is set to undergo significant transformations, particularly in the realm of directional control valves. One of the most exciting innovations in this space is the integration of smart technology. Smart directional control valves equipped with sensors can provide real-time data on system performance, enabling operators to optimize their hydraulic systems dynamically. This capability not only enhances efficiency but also aids in predictive maintenance, reducing downtime through timely interventions.

Moreover, advancements in materials science are leading to the development of lighter, more durable directional control valves. These new materials can withstand higher pressures and offer better corrosion resistance, ultimately extending the lifespan of hydraulic components. As industries push for more compact and efficient systems, the trend towards miniaturization of these valves is also gaining momentum, enabling them to fit into tighter spaces without sacrificing performance.

The incorporation of digital controls and automation continues to redefine how directional control valves function within hydraulic circuits. By enabling seamless integration with IoT platforms, these valves can enhance system automation, leading to improved responsiveness and performance. In the coming years, we can expect to see even more innovations that will not only enhance hydraulic efficiency but also contribute towards the sustainability goals many industries are striving for. With these advancements, directional control valves are poised to play a pivotal role in the future of hydraulic technology.

Related Video

-

Hydraulic Directional Control Valve @HydraulicPressChannel #hydraulic #hydraulics #powerpack

View: 6840Channel: Industrial Automation Solution -

6 functions Proportional valve max 120 l/min 350 bar Forest Crane 2 x Electric Joystick

View: 10721Channel: Hydraulic Master -

Hydraulic Directional Control Valves

View: 22206Channel: KletteTech

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry