- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

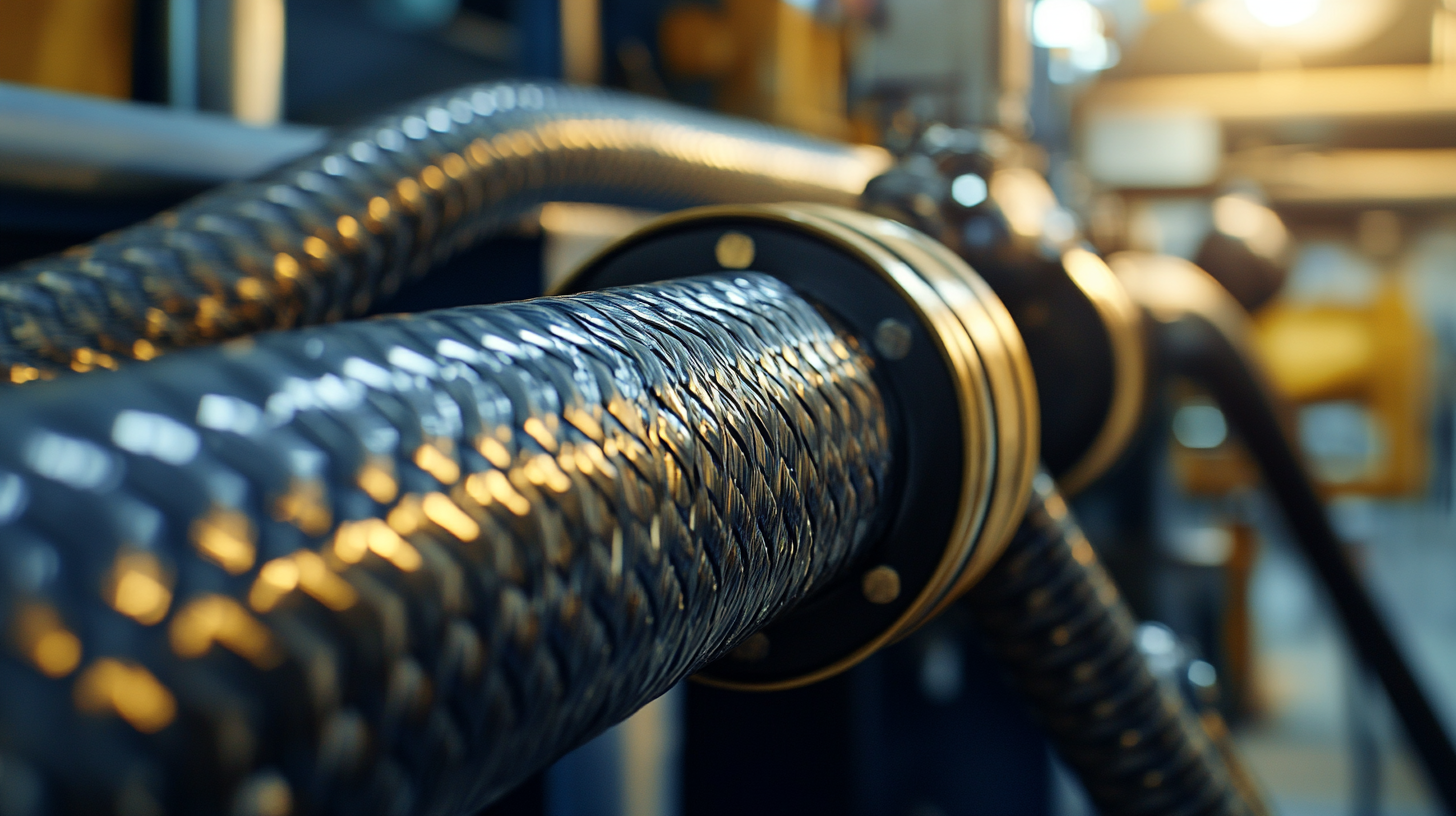

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

5 Key Advantages of Choosing the Right Industrial Hose for Your Business Needs

In the ever-evolving landscape of industrial operations, selecting the right tools can significantly impact efficiency and safety. Among these essential tools, the "Industrial Hose" plays a pivotal role in fluid transfer applications across various sectors. According to a recent market analysis by Grand View Research, the global industrial hose market is projected to reach $18.56 billion by 2025, driven by increasing demand across the oil and gas, construction, and manufacturing industries. Such statistics underline the importance of investing wisely in high-quality industrial hoses that not only meet specific operational requirements but also enhance overall productivity.

Furthermore, the proper selection of industrial hoses can lead to substantial cost savings and reduced downtime. A report by MarketsandMarkets estimates that improper hose management can inflate maintenance costs by as much as 30%. With a variety of options available, including material compositions, sizes, and pressure ratings, identifying the right industrial hose tailored to your business needs can drastically improve operational efficiency. In this blog, we will explore five key advantages of choosing the right industrial hose, ensuring your business is equipped for success in a competitive market.

Understanding the Importance of Selecting the Correct Industrial Hose for Your Operations

Choosing the right industrial hose is a critical decision that can significantly affect the efficiency and safety of your operations. The correct hose not only facilitates smooth transportation of fluids but also enhances productivity and minimizes downtime. Understanding the unique requirements of your business is essential when selecting an industrial hose, as various factors such as temperature, pressure, and chemical compatibility play a vital role in performance. Additionally, the right industrial hose can lead to long-term cost savings. Investing in high-quality hoses that resist wear and tear can prevent frequent replacements, reducing operational disruptions and maintenance costs. Moreover, hoses that are specifically designed for your application can improve overall system reliability, ensuring that your operations run smoothly without unexpected failures. Safety is another paramount consideration. Using inappropriate hoses can result in leaks, spills, or even hazardous situations for workers. Selecting the correct industrial hose with adequate specifications helps mitigate these risks, ensuring a safer work environment. Understanding the importance of these factors not only empowers businesses but also contributes to a more sustainable operational framework that can adapt to evolving industry standards and practices.

How the Right Industrial Hose Contributes to Enhanced Safety in the Workplace

When it comes to maintaining a safe and efficient workplace, the choice of industrial hose can play a pivotal role. The right industrial hose is not just about fulfilling operational needs; it significantly contributes to enhanced safety measures across various industries. A properly selected hose reduces the risk of leaks, bursts, and other failures that could lead to hazardous conditions for employees and equipment alike.

One of the primary advantages of using the correct industrial hose is its ability to withstand specific pressures and temperatures unique to different applications. Hoses designed for high-pressure environments mitigate the risk of catastrophic failures, while those meant for transporting chemicals are constructed to resist corrosive substances, ensuring that leaks do not occur. This level of durability not only protects the integrity of the materials being moved but also safeguards workers from exposure to harmful substances.

Moreover, the right industrial hose often comes with features that enhance visibility and maneuverability, such as color coding or abrasion-resistant exterior layers. These features help prevent accidents by making hoses more noticeable in busy workspaces, reducing the likelihood of tripping hazards. Additionally, the correct hose fittings and connections can prevent disconnections or spills, further promoting a safe work environment. By prioritizing the selection of industrial hoses that meet both operational needs and safety standards, businesses can create a safer workplace for all employees.

Boosting Efficiency: The Role of the Right Hose in Streamlining Processes

When it comes to optimizing operational efficiency in industrial settings, the importance of selecting the right hose cannot be overstated. The right industrial hose plays a pivotal role in streamlining processes, ensuring that materials are transported safely and effectively. This choice directly impacts both productivity and safety, as an inappropriate hose can lead to leaks, downtime, and costly repairs.

Moreover, the right hose is designed to handle specific applications, whether transferring fluids, gases, or materials under varying pressures and temperatures. By choosing a hose that fits the unique demands of your business, you enhance performance and extend equipment life, minimizing interruptions that can derail projects. For example, using hoses that resist abrasion and weathering can protect against wear and tear, ensuring uninterrupted operation throughout your workflow.

Additionally, selecting a hose that complies with industry standards and regulations can contribute to a safer working environment. It reduces the risk of accidents that might result from equipment failures or material spills, thus protecting your workforce and your bottom line. By investing time and resources in selecting the correct industrial hose, businesses can greatly enhance their operational efficiency and reliability, positioning themselves for long-term growth and success.

Cost Savings: Long-Term Benefits of Investing in Quality Industrial Hoses

Investing in quality industrial hoses can yield significant cost savings for businesses in the long run. While the initial expenditure on high-grade hoses may be higher, the durability and reliability they offer can drastically reduce maintenance and replacement costs. By choosing hoses that are designed to withstand specific industrial conditions, businesses can minimize downtime due to hose failures and the associated costs.

Moreover, quality hoses improve efficiency in operations. Industrial processes often require the seamless transfer of fluids and gases, and using subpar hoses can lead to leaks and contamination. These inefficiencies can result in lost materials and increased operational costs. By investing in hoses that are specifically engineered for their environment, businesses can avoid these pitfalls and ensure consistent performance, ultimately translating to improved profit margins.

Furthermore, quality industrial hoses contribute to safety and compliance. Substandard hoses can pose significant hazards, leading to accidents that not only endanger employees but also result in costly legal repercussions and fines. Quality hoses, crafted to meet stringent safety standards, can prevent these risks and foster a safer work environment, reinforcing the value of investing in quality both for financial and safety reasons.

Tailoring Industrial Hoses to Meet Specific Industry Requirements and Standards

When it comes to selecting industrial hoses, understanding the specific requirements of your industry is paramount. Different sectors, such as food processing, chemical manufacturing, and construction, have unique demands that dictate the type of hose needed. For instance, food-grade hoses must meet stringent hygiene standards, ensuring that no contaminants are introduced during transportation. This means choosing hoses made from materials that are non-toxic and easy to clean, thus maintaining the safety and quality of the products they carry.

Moreover, the durability and performance of hoses can vary significantly based on their intended use. High-pressure environments, such as those found in oil and gas applications, necessitate hoses that can withstand extreme conditions without failure. It is crucial to select hoses that are engineered to resist corrosive chemicals or high temperatures based on your specific operational needs. By tailoring your hose selection to meet these standards, businesses can avoid costly downtimes and ensure smooth operations.

In addition, regulatory compliance is another critical reason for customizing industrial hoses. Different industries are subjected to various regulations regarding safety and environmental standards. Choosing hoses that adhere to these regulations not only helps prevent legal issues but also fosters a safer workplace. Companies that invest in the right hoses tailored to their industry requirements are not only enhancing operational efficiency but also demonstrating a commitment to safety and quality standards.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry