- Home Page

- Company Profile

-

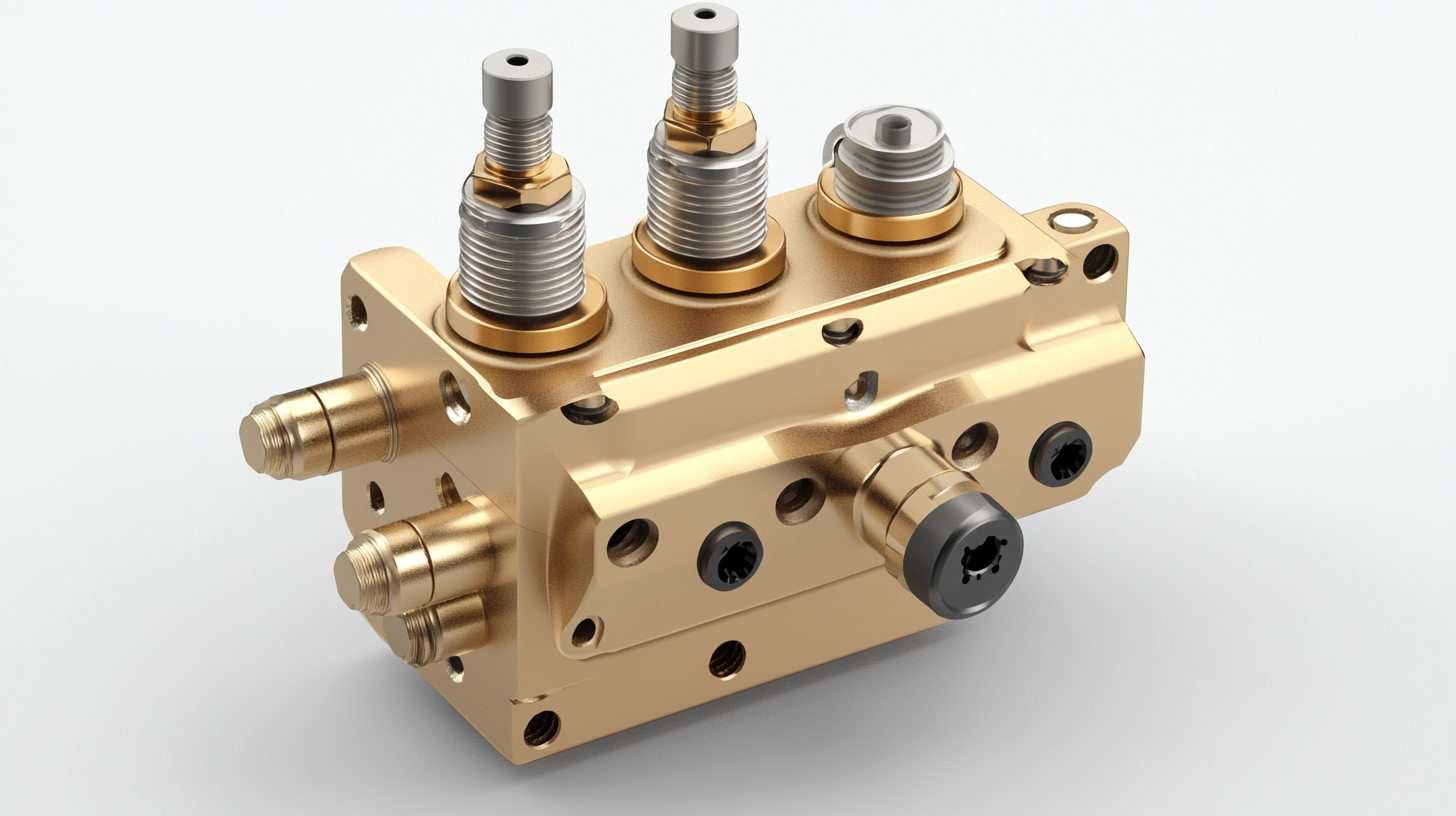

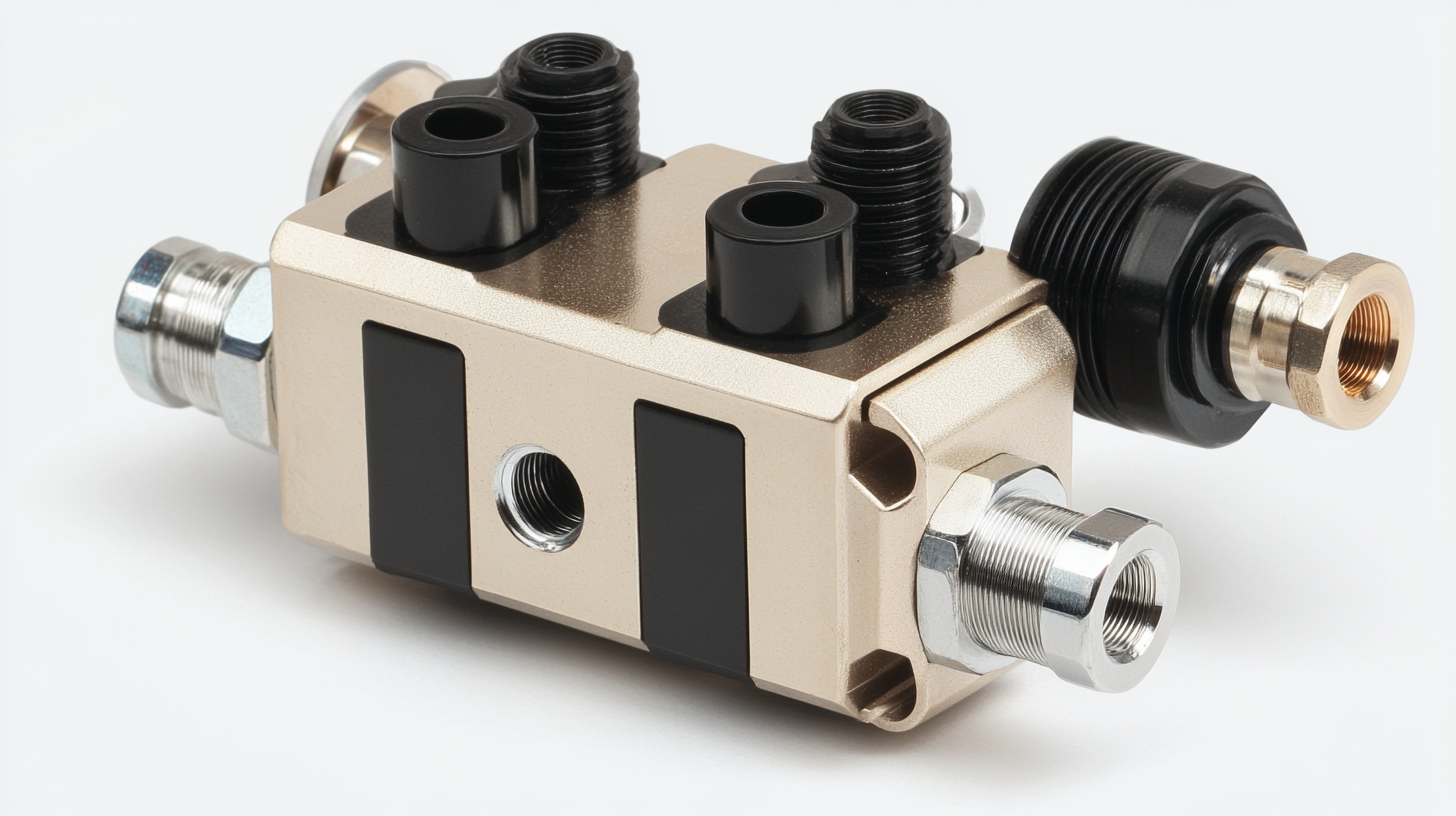

Our Products

- Hydraulic Pumps

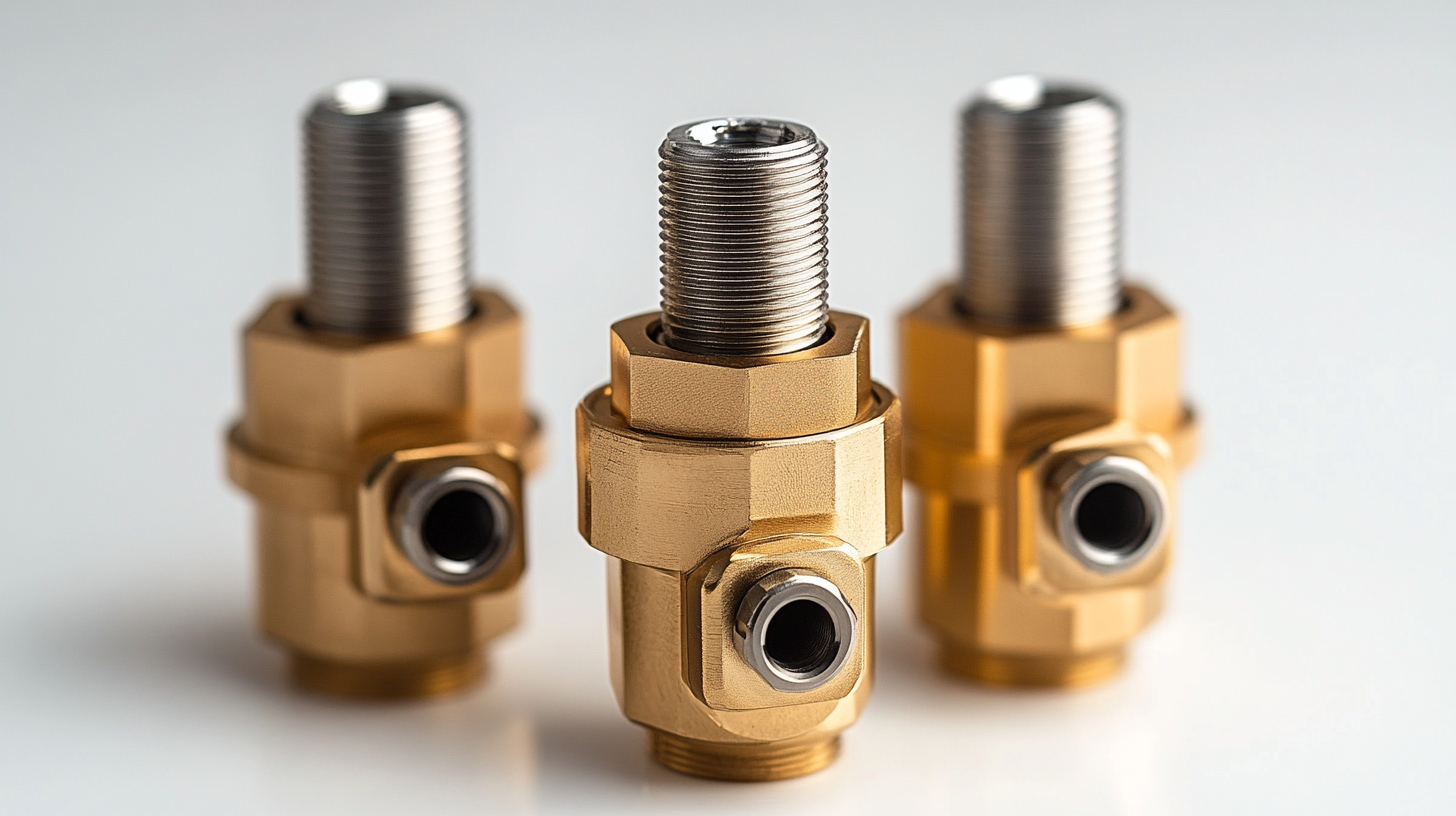

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

Top 5 Factors Driving Demand for Hydraulic Solenoid Valves in Global Markets

In recent years, the demand for Hydraulic Solenoid Valves has surged in global markets, driven by a multitude of factors that underline the growing significance of these components in various industrial applications. As a crucial element in automation and control systems, hydraulic solenoid valves are essential for regulating fluid flow and pressure in hydraulic systems, enabling enhanced efficiency and reliability across diverse sectors. The increasing emphasis on advanced technology and automation further accelerates the need for these valves, making them an integral part of modern machinery and equipment.

Several key factors contribute to the heightened demand for hydraulic solenoid valves, including the expansion of the manufacturing sector, rising infrastructure projects, and the push towards energy-efficient solutions. Additionally, industries are increasingly adopting IoT and smart technologies, which rely on precise control mechanisms that hydraulic solenoid valves can provide. This blog will explore the top five factors driving the demand for Hydraulic Solenoid Valves in global markets, shedding light on how they are shaping the future of industrial operations.

Growing Industrial Automation and Its Effect on Hydraulic Solenoid Valve Demand

The rise of industrial automation is significantly impacting the demand for hydraulic solenoid valves across global markets. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach $300 billion by 2025, growing at a CAGR of 9.3% from 2020. This surge translates directly into increased use of hydraulic systems in various sectors such as manufacturing, automotive, and construction, where efficient control of fluids is essential. Hydraulic solenoid valves play a pivotal role in these applications, managing the flow and direction of hydraulic fluid in machinery with precision. In particular, the need for smarter, more efficient industrial processes has led to a growing reliance on automated hydraulic systems. A report from Research and Markets highlights that the automation of manufacturing processes reduces downtime and increases productivity by up to 20%. As industries strive to enhance operational efficiency, the demand for components such as hydraulic solenoid valves, which facilitate quick and reliable actuation, is expected to rise. Moreover, technological advancements in the fields of control systems and IoT (Internet of Things) have further fueled the adoption of hydraulic solenoid valves. The integration of IoT allows for real-time monitoring and analysis, enabling operators to optimize performance and reduce maintenance costs. According to the International Federation of Robotics, the deployment of industrial robots, which often rely on hydraulic actuation, is anticipated to exceed 3 million units by 2025. This growing trend underscores the essential role of hydraulic solenoid valves in supporting automation and enhancing system reliability in modern industrial environments.

Emergence of Renewable Energy Projects Influencing Market Trends

The emergence of renewable energy projects is significantly reshaping market dynamics, particularly in Asia, where electricity prices are increasingly influenced by the costs associated with integrating renewable energy sources. According to recent industry data, the expansion of solar and wind projects, alongside energy storage solutions, is driving a paradigm shift in how energy is produced and consumed. This impact is evident as Asia aims to reduce dependency on fossil fuels, adapting its infrastructure to accommodate greener energy technologies.

The integration of renewable energy brings challenges, notably in energy management and cost-effectiveness. Battery storage technologies, essential for balancing supply and demand, are expected to become vital components of this evolving landscape. A report from a leading market research firm indicates that the global battery market is projected to grow at a compound annual growth rate (CAGR) of over 25% through 2030, suggesting a robust appetite for innovative solutions that enhance grid stability while lowering costs.

Moreover, the rise of artificial intelligence (AI) in various sectors introduces additional complexities. AI’s rapid expansion contributes to increased energy consumption, raising concerns over carbon emissions linked to data centers. As these facilities consume vast amounts of electricity, optimizing energy use without compromising performance has become a pressing challenge. Industry analysts emphasize the need for developing energy-efficient AI models to mitigate environmental impacts, indicating that data centers may need to adapt by investing in renewable energy sources and advanced cooling technologies to reduce their overall carbon footprint.

Technological Advancements in Valve Systems and Their Market Implications

Technological advancements in valve systems are playing a crucial role in driving demand for hydraulic solenoid valves across global markets. As industries increasingly seek efficiency and reliability, innovations such as automation, smart valve technology, and integration with IoT devices have dramatically transformed operational capabilities. Manufacturers are prioritizing the development of valves that not only enhance performance but also comply with stricter regulatory standards, a trend that is evident in various sectors, including automotive and industrial applications.

One significant trend is the evolution of proportional valves, which are adapting to meet the needs of demanding applications. These advancements enable more precise control of fluid flow, which is essential for optimizing processes in hydraulic systems. With the continuous push towards automation and improved system integration, the hydraulic solenoid valve market is expected to benefit from increased adoption rates across various industries, including construction, manufacturing, and water treatment.

Moreover, the growth in associated markets, such as the global ball valves market, further highlights the importance of innovative valve systems. With projected revenue growth and a compound annual growth rate (CAGR) of 4.7%, the synergy between technological advancement and market demand indicates a promising future for hydraulic solenoid valves. As manufacturers invest in R&D to harness new technologies, they will not only meet current market needs but also pave the way for future developments in hydraulic applications.

Increasing Construction and Infrastructure Development Driving Solenoid Valve Needs

The construction and infrastructure development sectors are seeing unprecedented growth globally, and this boom is significantly influencing the demand for hydraulic solenoid valves. As projects become more complex and require precise control and automation, solenoid valves have emerged as essential components in various hydraulic systems. These valves facilitate the efficient management of fluids, ensuring that operations continue smoothly and safely in diverse applications, from heavy machinery to automated assembly lines.

Moreover, as governments and private entities allocate more resources towards infrastructure projects, such as roads, bridges, and public transport systems, the need for reliable hydraulic systems becomes paramount. Solenoid valves play a critical role in maintaining the functionality of hydraulic equipment, which is vital in executing these large-scale projects effectively. The increased focus on sustainability and efficiency in construction further drives the adoption of advanced hydraulic solutions, making solenoid valves indispensable in achieving these objectives.

In addition to traditional construction activities, the rise of smart cities and urban development initiatives is generating a new wave of demand for hydraulic solenoid valves. Modern infrastructure increasingly integrates automation and smart technologies that rely on precise hydraulic control. As cities evolve to meet the challenges of population growth and urbanization, the role of solenoid valves in supporting innovative solutions will continue to expand, reinforcing their importance in the global market.

Rising Demand for High-Efficiency Hydraulic Systems Across Various Sectors

The rising demand for high-efficiency hydraulic systems is a pivotal trend influencing the global market for hydraulic solenoid valves. As industries strive for improved performance and reduced operational costs, these valves are essential components in maximizing the efficiency of hydraulic systems. According to a recent report by ResearchAndMarkets, the hydraulic equipment market is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This growth underscores the increasing emphasis on developing more energy-efficient solutions across various sectors, including manufacturing, construction, and agriculture.

One of the primary drivers of this trend is the escalating need for automation and precision control in hydraulic systems. The International Federation of Robotics indicates that global industrial robot installations increased by 12% in 2021, highlighting a significant shift toward automated machinery that relies heavily on hydraulic functionality. As a result, manufacturers are increasingly integrating hydraulic solenoid valves into these systems to enhance performance, responsiveness, and energy conservation.

Furthermore, the push for sustainability is prompting industries to adopt hydraulic solutions that minimize energy consumption and waste. A report from the American Society of Mechanical Engineers (ASME) mentions that hydraulic systems equipped with high-efficiency solenoid valves can reduce energy usage by as much as 30%. This efficiency is particularly critical in sectors such as mining and oil and gas, where operational efficiency directly correlates with environmental impact and regulatory compliance. As these industries look to innovate and adhere to stricter regulations, the demand for advanced hydraulic solenoid valves will continue to rise.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry