- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

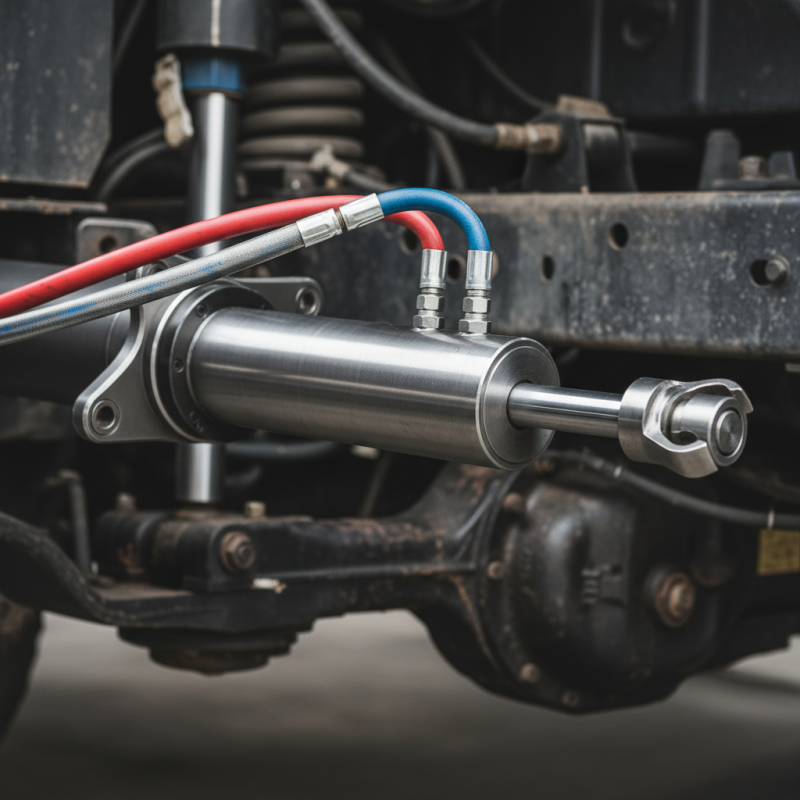

What is a Steering Cylinder and How Does It Work?

The Steering Cylinder is a vital component in many vehicles. It plays a crucial role in the steering system's efficiency. This hydraulic device helps control the direction of the vehicle with ease and precision.

A Steering Cylinder converts hydraulic pressure into mechanical movement. This process allows for smooth steering responses. It is fascinating how such a small part can impact driving. However, many overlook its importance until it malfunctions. Regular maintenance is essential. Ignoring small issues can lead to larger problems later.

Drivers often take for granted how effortlessly they can navigate roads. Steering Cylinders provide that ease. Yet, when they fail, the frustration begins. Understanding this component helps drivers appreciate their vehicles' engineering. An informed driver is a safer driver. Reflecting on this might inspire better care for our vehicles.

What is a Steering Cylinder?

A steering cylinder is a vital component in hydraulic steering systems. It helps to convert hydraulic pressure into mechanical movement. This allows for smoother and more responsive handling of vehicles. According to industry data, steering cylinders can significantly enhance vehicle maneuverability, especially for larger vehicles like trucks and buses.

The design of a steering cylinder is relatively straightforward. It consists of a cylinder housing, piston, and rod. When hydraulic fluid enters the cylinder, it pushes the piston, which moves the connected rod. This movement turns the vehicle's wheels. However, the efficiency of steering cylinders can vary based on design and maintenance. Inadequate maintenance can lead to leaks and reduced performance, impacting vehicle safety. Studies indicate that up to 20% of steering-related accidents are linked to faulty components, including worn steering cylinders.

Many engineers are now exploring advanced materials to improve durability. The focus is on enhancing resistance to wear and corrosion. However, the implementation of these new materials may increase production costs. Some manufacturers may hesitate to invest in these technologies. This creates a gap between innovation and practical application in the industry. Overall, the steering cylinder plays a crucial role, but it requires attention to detail in both design and maintenance.

The Basic Components of a Steering Cylinder

A steering cylinder is a crucial part of hydraulic steering systems. It plays a key role in controlling the direction of a vehicle. Understanding its basic components helps in grasping how it functions effectively.

The primary component is the cylinder itself. It contains hydraulic fluid under pressure. This fluid moves a piston, which creates force. A rod attached to the piston extends out of the cylinder, connecting to the steering mechanism. This rod’s movement translates into steering action.

Another important element is the seals. They prevent fluid leaks and maintain pressure. Without these seals, performance suffers, leading to inefficiencies. Additionally, hoses supply the hydraulic fluid to the cylinder. Their integrity is vital for a seamless operation. Overall, while steering cylinders are effective, they can face wear and tear, leading to challenges in performance. Regular maintenance can address these issues, ensuring reliable steering control.

How Steering Cylinders Facilitate Vehicle Maneuvering

Steering cylinders play a crucial role in vehicle maneuvering. They are essential components in hydraulic steering systems. According to industry reports, over 70% of modern vehicles utilize hydraulic systems, where steering cylinders provide the necessary force for precise control. This force translates into effective steering, allowing for swift turns and smooth navigation.

In practice, steering cylinders operate by converting hydraulic pressure into linear motion. When the driver turns the steering wheel, hydraulic fluid flows into the cylinder. A piston inside pushes the linkage components, which ultimately turns the vehicle's wheels. However, performance can vary based on design and maintenance. Studies indicate that poorly maintained steering systems can lead to a 15% decrease in efficiency. Regular checks are essential to ensure responsiveness and safety.

Despite the advancements, challenges remain. Some systems can develop leaks, leading to reduced steering power. Drivers may experience a delay in responsiveness. This highlights the importance of regular inspections. A well-functioning steering cylinder improves control, enhancing safety on the road. However, neglecting maintenance could lead to dangerous situations. Awareness is key for safe vehicle operation.

The Fluid Dynamics Behind Steering Cylinder Operation

A steering cylinder plays a crucial role in vehicle steering systems. It uses hydraulic fluid to create force, allowing the driver to control the vehicle more effortlessly. Understanding the fluid dynamics involved can provide deeper insights into its operation.

When fluid enters the steering cylinder, it generates pressure, pushing a piston. This piston movement translates into steering motion. The hydraulic system amplifies the driver’s input, making steering easier. However, the efficiency of this system can be affected by factors like fluid viscosity and temperature. If the fluid is too thick, it might not flow smoothly, leading to sluggish steering.

Another consideration is the potential for leaks. Over time, seals can wear, causing fluid loss. This could significantly reduce the system’s effectiveness. Drivers may notice a delayed response or increased effort required to steer. It’s important to regularly check the fluid levels and inspect for leaks. Addressing these issues early can help maintain optimal performance and enhance safety on the road.

What is a Steering Cylinder and How Does It Work? - The Fluid Dynamics Behind Steering Cylinder Operation

| Dimension | Value | Unit | Description |

|---|---|---|---|

| Bore Diameter | 50 | mm | The inner diameter of the cylinder where the fluid flows. |

| Rod Diameter | 30 | mm | The diameter of the piston rod that extends out of the cylinder. |

| Stroke Length | 100 | mm | The distance the piston can move within the cylinder. |

| Operating Pressure | 200 | bar | The pressure at which the hydraulic system operates. |

| Fluid Type | Hydraulic Oil | - | The type of fluid used for the operation of the steering cylinder. |

| Cycle Time | 0.5 | s | Time taken for one complete extension and retraction of the piston. |

| Mounting Type | Clevis | - | Type of connection for the cylinder to the system. |

Common Applications and Types of Steering Cylinders

Steering cylinders are critical components in various machinery and vehicles. They help to control the direction of travel through hydraulic or pneumatic means. Understanding their applications can highlight their importance in daily operations.

Common applications of steering cylinders include automotive steering systems, forklifts, and agricultural machinery. In cars, they facilitate smooth steering, ensuring a responsive driving experience. Forklifts use them to maneuver and lift loads efficiently. Agricultural equipment also relies on steering cylinders to navigate uneven terrains and perform tasks effectively.

The types of steering cylinders vary based on their use. Hydraulic cylinders are prevalent, creating significant force with minimal effort. Pneumatic cylinders offer a lighter option, ideal for specific applications. Each type has its advantages and limitations. Fitting the right type is crucial for performance, yet many overlook this during installations. Proper selection requires a deep understanding of the machinery's needs.

Article Source:

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry