- Home Page

- Company Profile

-

Our Products

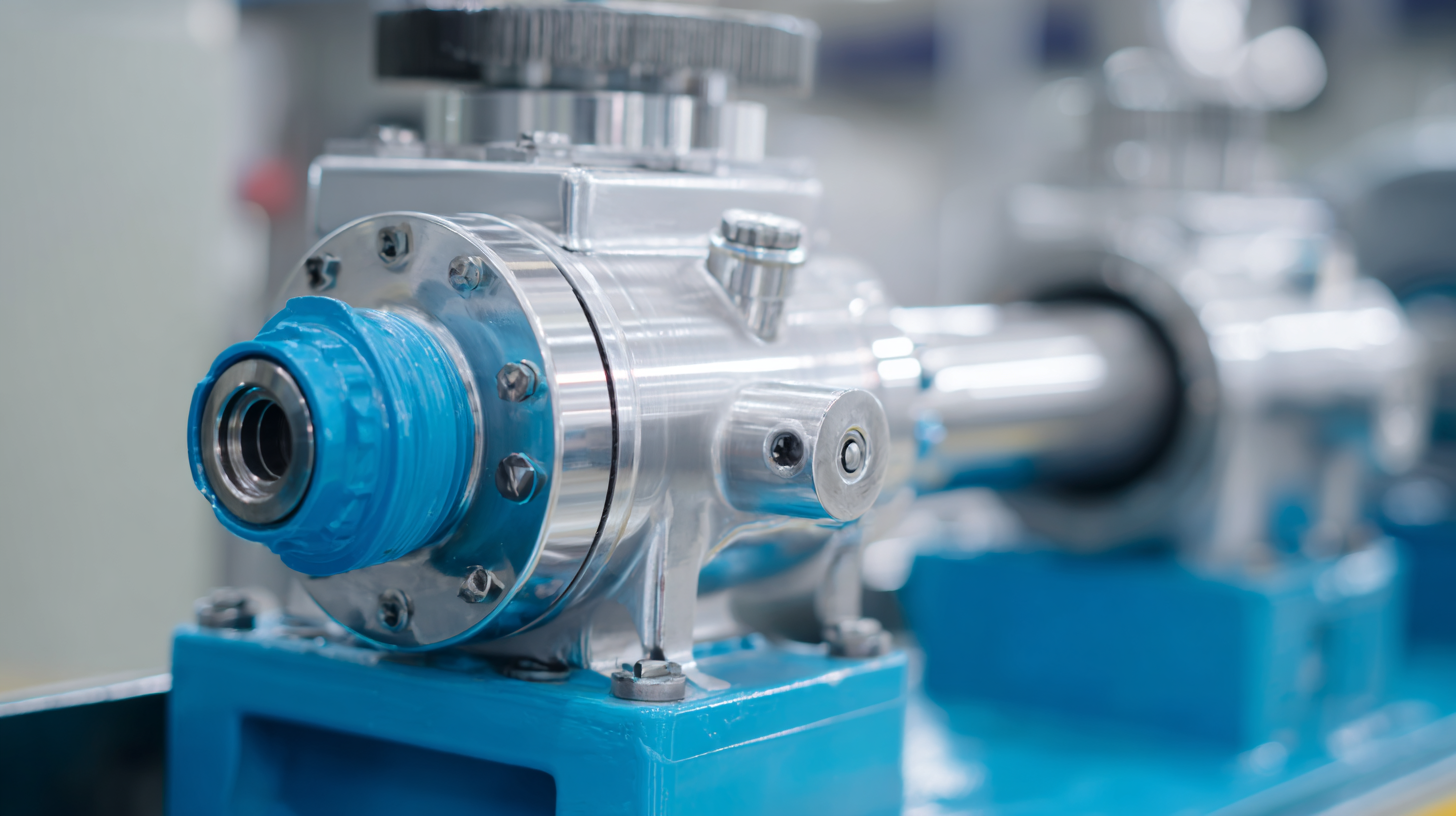

- Hydraulic Pumps

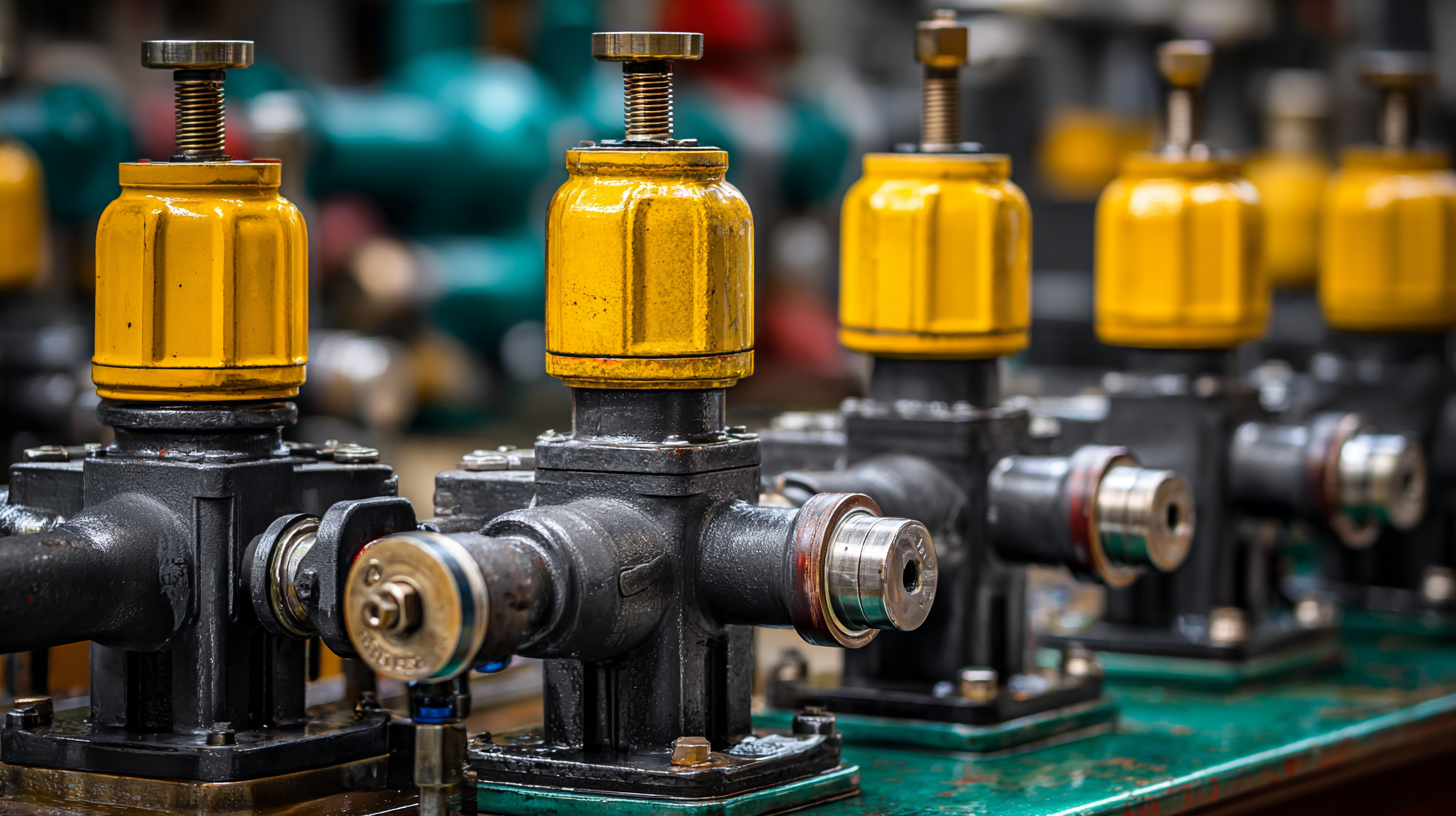

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

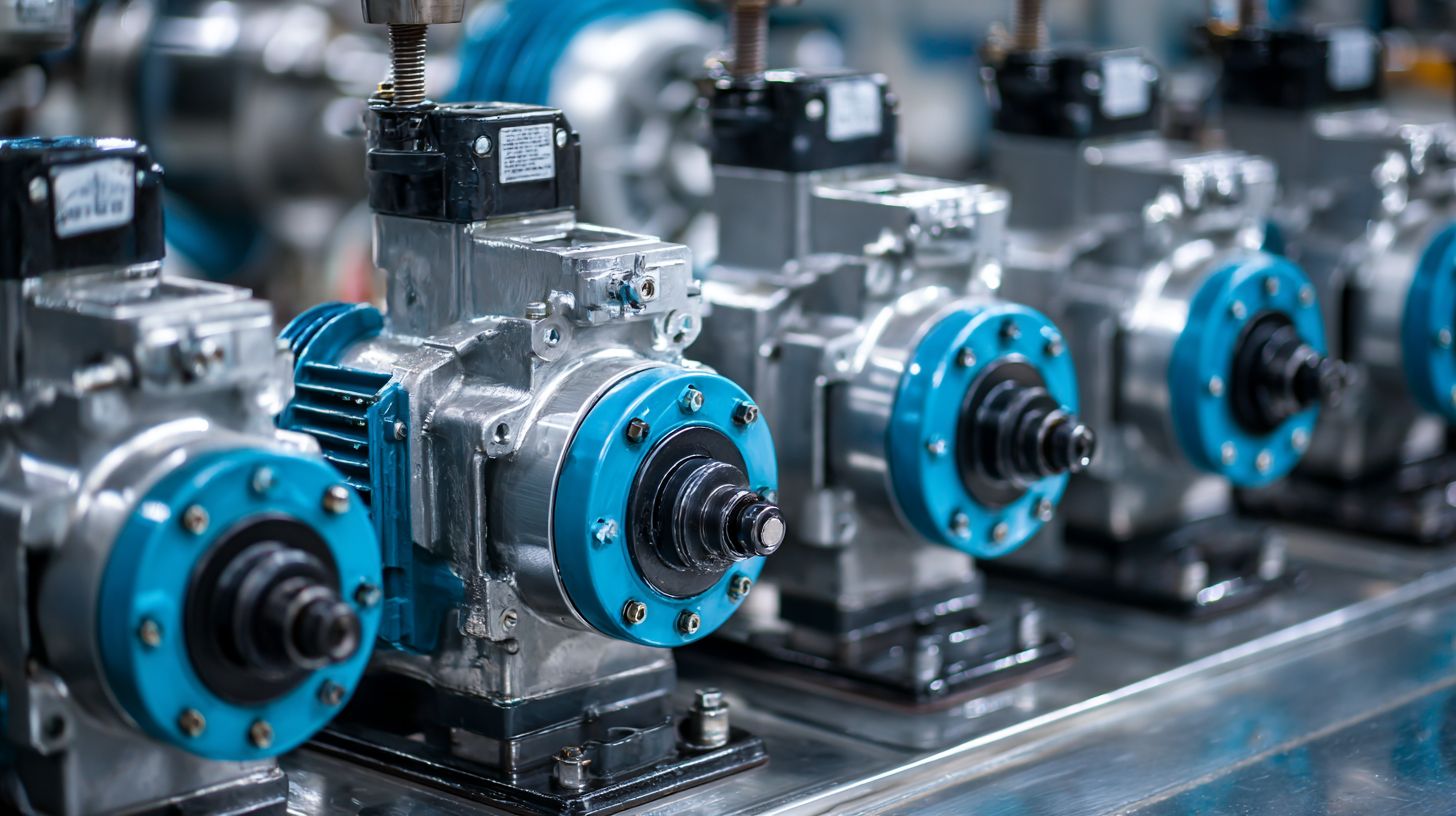

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

Discovering Top Applications for Best Gear Pumps in Global Industries

In the ever-evolving landscape of global industries, gear pumps have emerged as vital components driving efficiency and performance in various applications. According to a recent market research report by Grand View Research, the global gear pump market size was valued at USD 2.57 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028. As industries increasingly demand robust and reliable fluid transfer solutions, the versatility and precision of gear pumps make them indispensable in sectors ranging from automotive and manufacturing to oil and gas. This tutorial will explore the top applications of gear pumps across these industries, highlighting their unique advantages and contributions to enhanced operational effectiveness. By understanding the pivotal role of gear pumps, businesses can harness their potential to optimize productivity and drive innovation in their respective fields.

Exploring the Versatility of Gear Pumps in Various Industrial Applications

Gear pumps are integral to numerous global industries, known for their reliability and efficiency in fluid transfer. Their ability to handle high-viscosity fluids makes them indispensable in sectors such as oil and gas, chemical processing, and food production. According to a market research report by Grand View Research, the global gear pump market is expected to reach USD 4.85 billion by 2025, driven largely by the growing demand for advanced pumping solutions in diverse industrial applications.

In the automotive industry, gear pumps are used in hydraulic systems to ensure optimal performance and safety. The American Institute of Chemical Engineers reports that gear pumps are capable of providing a consistent flow rate, which is critical for systems that require precision under varying operating conditions. Furthermore, their versatility extends to pharmaceutical manufacturing, where precise dosing is essential. The increasing demand for pharmaceuticals is projected by MarketsandMarkets to drive a CAGR of 5.5% in the gear pump market through 2027, highlighting the role of these pumps in meeting industry standards and regulations.

These applications illustrate not only the versatility of gear pumps but also their critical role in enhancing operational efficiency across various sectors. With ongoing advancements in technology, the capabilities of gear pumps continue to evolve, making them a key component in the modernization of industrial processes worldwide.

Applications of Gear Pumps in Global Industries

Comparing Gear Pump Alternatives: Advantages and Limitations

When exploring the world of gear pumps across various industries, it's essential to compare alternatives to find the best fit for specific applications. Gear pumps are known for their reliability and efficiency, but not all designs suit every situation. Understanding the advantages and limitations of different gear pump models can help businesses make informed decisions.

For instance, traditional gear pumps offer excellent viscosity handling and are generally more affordable, but they may not perform as well under high pressures. On the other hand, advanced designs such as external gear pumps provide higher efficiency and potentially longer lifespans, though they may come with increased initial costs. Investing in the right gear pump can significantly impact operational performance, making it crucial to evaluate not just the technical specifications, but also how the pump fits within the larger system.

As industries continue to evolve and require more specialized solutions, the need for comprehensive comparisons becomes even more apparent. Businesses must weigh the pros and cons of each gear pump design, aiming for balance between performance, cost, and durability to ensure optimal operational efficiency.

Discovering Top Applications for Best Gear Pumps in Global Industries - Comparing Gear Pump Alternatives: Advantages and Limitations

| Application | Gear Pump Type | Advantages | Limitations |

|---|---|---|---|

| Petroleum Industry | Internal Gear Pump | High efficiency in thick fluids | Higher cost compared to external types |

| Food Processing | External Gear Pump | Sanitary design, easy to clean | Limited viscosity range processing |

| Chemical Manufacturing | Gear Pump with Magnetic Drive | Prevents leakage of hazardous materials | Higher initial investment |

| HVAC Systems | High-Pressure Gear Pump | Handles higher operational pressures | More complex maintenance |

| Automotive Industry | Compact Gear Pump | Space-saving, lightweight | Limited flow rates |

Innovative Applications of Gear Pumps in Emerging Industries

Gear pumps have emerged as crucial components across various industries, demonstrating their versatility and advanced engineering. In recent studies, the demand for gear pumps is projected to grow at a CAGR of 5.4% from 2023 to 2030, driven by advancements in manufacturing processes and the increasing need for efficient fluid transfer systems. Emerging industries, such as renewable energy and electric vehicles, are leveraging gear pumps for their reliability and precision, contributing to sustainability efforts worldwide.

Gear pumps have emerged as crucial components across various industries, demonstrating their versatility and advanced engineering. In recent studies, the demand for gear pumps is projected to grow at a CAGR of 5.4% from 2023 to 2030, driven by advancements in manufacturing processes and the increasing need for efficient fluid transfer systems. Emerging industries, such as renewable energy and electric vehicles, are leveraging gear pumps for their reliability and precision, contributing to sustainability efforts worldwide.

In the renewable energy sector, gear pumps are instrumental in hydraulic systems that support wind turbines and solar power installations. According to a report by the International Renewable Energy Agency (IRENA), the global renewable energy workforce exceeded 11 million in 2018, indicating a robust market for gear pump applications in ensuring seamless operations within this booming sector.

Tip: When selecting gear pumps for emerging applications, consider the compatibility with various fluids and pressurized systems to ensure optimal performance and longevity. Additionally, regular maintenance and monitoring can significantly enhance the reliability of pump systems in high-demand environments.

Moreover, in the electric vehicle sector, gear pumps are used in battery cooling systems and hydraulic brakes. The global electric vehicle market is expected to reach 31.1 million units by 2030, a figure that highlights the growing significance of gear pumps in enhancing their efficiency and safety.

Tip: Always opt for pumps with advanced materials and coatings to withstand environmental stresses, ensuring that your gear pumps perform well under challenging conditions.

Assessing the Performance of Alternative Pump Technologies

When considering the performance of alternative pump technologies, it's important to assess their efficiency, durability, and maintenance requirements. Gear pumps, known for their precision and reliability, are often pitted against other technologies such as diaphragm and screw pumps. Each has its unique advantages; for instance, diaphragm pumps are excellent for handling corrosive fluids, while screw pumps can manage high-viscosity substances effortlessly. Understanding these strengths can lead to better application choices in various industries.

Tip: Always conduct a thorough compatibility check when selecting a pump for your specific application. Ensure the materials used in the pump can withstand the required temperatures and chemical exposures. This decreases the likelihood of malfunctions and extends the service life of the equipment.

Moreover, energy efficiency is a crucial factor when evaluating pump technologies. Modern gear pumps are designed to provide high performance with lower energy consumption, making them a favorable option for industries looking to reduce operational costs. In contrast, alternative technologies may require more power, especially under demanding conditions.

Tip: Consider implementing variable frequency drives (VFDs) with your pumps. VFDs allow for real-time adjustments in pump performance, optimizing energy usage and adapting to varying operational demands efficiently.

Key Factors in Selecting the Right Gear Pump Alternative for Your Needs

When selecting the right gear pump for industrial applications, several key factors must be considered to ensure optimal performance and efficiency. One such factor is the pump’s material construction, which can significantly impact its durability and ability to handle various fluids. According to a recent report by Market Research Future, the gear pump market is projected to reach $4.3 billion by 2025, driven by increasing demand in sectors such as oil and gas, chemicals, and food processing. This highlights the importance of choosing a pump that can withstand the specific environmental conditions of your industry.

Another critical consideration is the size and design of the gears within the pump. Gear pumps operate on the principle of enclosed fluids being transported by rotating gears, and the gear profile can greatly influence the flow rate and pressure characteristics. Research indicates that high-efficiency gear pumps can improve energy consumption by up to 15%, making them a cost-effective choice for businesses aiming to reduce operational costs. Additionally, factors such as viscosity, temperature, and the nature of the fluid being pumped must be evaluated to select the appropriate pump that meets both performance requirements and regulatory standards in your industry.

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry