- Home Page

- Company Profile

-

Our Products

- Hydraulic Pumps

- Hydraulic Solenoid Valves

- Conventional Valves

- Proportional Valves

- Safety Valves

- Mobile Control Valves

- Hydraulic Motor

- Cylinders and Servo Cylinders

- Hydraulic Filters

- Hoses and Fittings

- Gates Hydraulic Hose

- MP Filters Filters

- Dowty Gear Pumps

- Polyhydron Valves

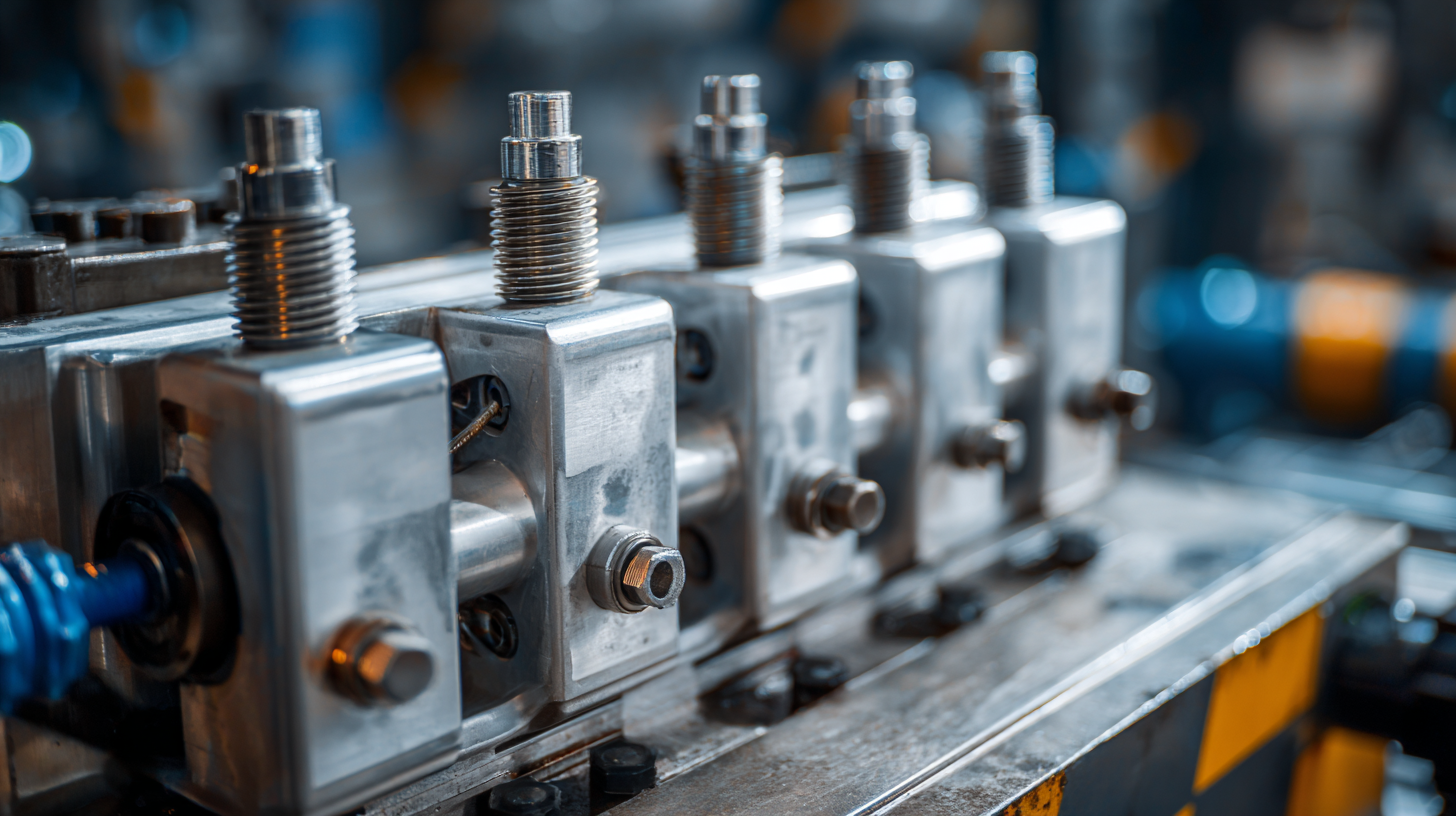

- Manifold Blocks

- Walvoil

- Spica

- Hand Pumps

- ATOS Hydraulic Components

- Blog

5 Top Benefits of Gates Hydraulic Systems for Enhanced Efficiency in Industrial Applications

In today's competitive industrial landscape, the demand for increased efficiency and reliability is more crucial than ever. According to a recent report by Research and Markets, the global hydraulic systems market is projected to reach $60 billion by 2026, driven by industries seeking innovative solutions to enhance performance. Gates Hydraulic systems stand out as a key player in this domain, offering advanced technology that improves operational uptime and reduces energy consumption. The versatility and durability of Gates Hydraulic solutions provide industries with the tools necessary to optimize processes, leading to significant cost savings and productivity gains. In this blog, we will explore the top five benefits of Gates Hydraulic systems that position them as indispensable assets in various industrial applications.

Understanding Gates Hydraulic Systems and Their Functionality

Gates hydraulic systems are engineered to maximize efficiency and reliability across a multitude of industrial applications. These systems utilize advanced hydraulic technology to deliver precise control and power, making them ideal for demanding environments. According to a report by MarketsandMarkets, the global hydraulic systems market is expected to reach $48.4 billion by 2025, highlighting the growing reliance on hydraulic technologies for operational enhancements.

The functionality of Gates hydraulic systems lies in their ability to optimize fluid power transmission, which is crucial for various industrial processes. Equipped with durable components and innovative designs, these systems reduce energy losses and improve cycle times. A study from the International Journal of Advanced Manufacturing Technology noted that implementing efficient hydraulic systems can improve machinery productivity by up to 20%. As industries continue to focus on lowering operational costs while increasing output, Gates hydraulic systems stand out as a practical solution for boosting overall efficiency and performance.

Key Advantages of Using Hydraulic Systems in Industrial Settings

Hydraulic systems have become integral in enhancing efficiency across various industrial applications. One of the most significant advantages of utilizing hydraulic systems is their ability to provide impressive force and power output in a compact form. For instance, compared to electric systems, hydraulic systems can generate higher torque, making them ideal for heavy-duty machinery and equipment. Reports indicate that the global automotive hydraulic system market is projected to grow from $47.43 billion in 2023 to $57.80 billion by 2030, reflecting a steady CAGR of 2.9%. This growth emphasizes the increasing reliance on hydraulic technology in industries.

Additionally, hydraulic systems facilitate rapid speed and accuracy in operational processes. Their capacity for precise control gives manufacturers the edge in producing high-quality products while minimizing waste. Tips for leveraging hydraulic systems include ensuring proper maintenance to prevent downtime and optimizing system design to meet specific application needs. Moreover, integrating advanced hydraulic technologies can lead to improved energy efficiency, which not only reduces costs but also supports sustainability goals. Employing these strategies can significantly enhance productivity and operational effectiveness in industrial settings.

Improved Energy Efficiency Through Hydraulic System Innovations

In today's industrial landscape, energy efficiency has become a paramount concern, and Gates hydraulic systems are at the forefront of innovations that address this need. By employing cutting-edge hydraulic technologies, these systems are designed to minimize energy consumption while maximizing operational performance. Advances such as variable displacement pumps and intelligent control systems allow for more precise energy usage, which significantly reduces waste and lowers operational costs.

Moreover, the integration of high-efficiency components ensures that energy is used effectively during various industrial processes. By optimizing the flow and pressure within hydraulic circuits, Gates systems can maintain peak performance with lower energy inputs. This combination of advanced engineering and energy-saving strategies not only contributes to reduced carbon footprints but also enhances overall productivity.

As industries continue to seek sustainable solutions, the innovations in Gates hydraulic systems present a compelling option for achieving greater energy efficiency and operational excellence.

Enhancing Safety and Reliability with Gates Hydraulic Technology

In today's industrial landscape, enhancing safety and reliability through advanced hydraulic technology is paramount. Hydraulic systems have evolved significantly, and their integration into industrial applications not only streamlines processes but also elevates safety measures. The global industrial hose market, projected to witness substantial growth from 2025 to 2030, highlights the increasing emphasis on specialized materials such as nitrile rubber and polyurethane, which are pivotal in developing more durable and reliable hydraulic systems. Such innovations contribute to safer environments by minimizing the risks associated with hydraulic failures.

Furthermore, the shift towards intelligent health diagnosis and maintenance decision-making is reshaping smart manufacturing. By employing cyber-physical systems (CPPS), industries can identify unexpected faults and mitigate risks effectively. This proactive approach to maintenance ensures that hydraulic systems operate at optimal efficiency, contributing to both operational reliability and worker safety. The investment in resilient hydraulic structures, like flood defenses founded on robust engineering principles, also underscores the commitment to future-proofing industrial processes. As companies focus on these advancements, the role of integrated hydraulic systems in ensuring operational excellence becomes increasingly clear, making them indispensable in modern industrial applications.

Comparative Analysis: Hydraulic vs. Traditional Industrial Systems

In the ever-evolving landscape of industrial applications, the choice between hydraulic systems and traditional mechanical systems has become paramount. Recent studies indicate that hydraulic systems can enhance operational efficiency by up to 30% compared to their traditional counterparts. This improvement stems primarily from the hydraulic system's ability to provide smoother and more controllable power transmission. Unlike mechanical systems that often suffer from wear and tear due to friction, hydraulic systems utilize fluid under pressure, resulting in decreased maintenance costs and increased longevity.

Moreover, hydraulic systems are known for their superior load-handling capabilities. According to data from the International Journal of Engineering Research, hydraulic machinery can lift loads up to 1,200% more than electromechanical systems of similar size. This provides industries such as construction and manufacturing with the flexibility to manage heavier loads without investing in additional machinery. Additionally, the compact design of hydraulic systems allows for more efficient use of space, a notable advantage in crowded industrial environments where every square foot counts.

5 Top Benefits of Gates Hydraulic Systems for Enhanced Efficiency in Industrial Applications

| Benefit | Hydraulic Systems | Traditional Systems |

|---|---|---|

| Increased Efficiency | High power-to-weight ratio allows for more efficient energy use. | Generally less efficient due to higher energy losses during operation. |

| Compact Design | Hydraulic systems typically require less space. | Bulky components take up more physical space. |

| Reduced Maintenance | Fewer moving parts leads to lower maintenance requirements. | More moving parts may result in higher maintenance demands. |

| Enhanced Control | Precise control over speed and torque. | Limited control options often lead to less precision. |

| Better Power Management | Ability to easily adjust power output for varying tasks. | Fixed power output leads to inefficiencies in varied applications. |

Related Posts

-

Challenges with Selecting the Right Gates Hoses for Your Operations

-

Unlocking Quality: The Definitive Handbook for Sourcing Gates Hoses Suppliers Worldwide

-

How to Optimize Your Pump Valve Selection for Maximum Efficiency

-

How to Choose the Best Ball Valves for Your Industry in 2025 Trends and Insights

-

Navigating Global Trade Certifications: How to Import Hoses and Fittings Successfully

-

Maximizing Efficiency and Minimizing Cost: The Role of Aftermarket Support in Industrial Hose Fittings

Developed and Managed byInfocom Network Private Limited.

Send Inquiry

Send Inquiry